Earlier this year I purchased the K-PRO (version 3) engine computer tuning solution made by Hondata, Inc. This modified ECU would open up my 2002 Civic Si (EP3) to performance tuning. While there are a couple engine tuning solutions available for my car, the Hondata K-PRO is the most common and well-supported. I’ve seen King’s skillful dyno tuning and was looking forward to having some tuning done to make the most of my car’s modest modifications.

PURCHASE & CONVERSION

To prepare, I picked up an un-modified ECU for my EP3 -- the PNF version, which is the same as what comes with the EP3. I bought this ECU second hand, from a reputable seller. Placing the order with King Motorsports was easy. Scott from King pointed me to a form to fill out and send in with my ECU to Hondata’s facility in Torrance, California. Scott had to fill in some paperwork on his end as well so that Hondata would be prepared for my ECU.

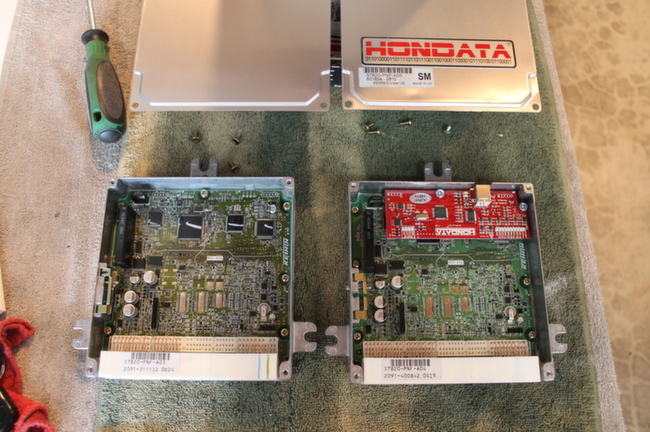

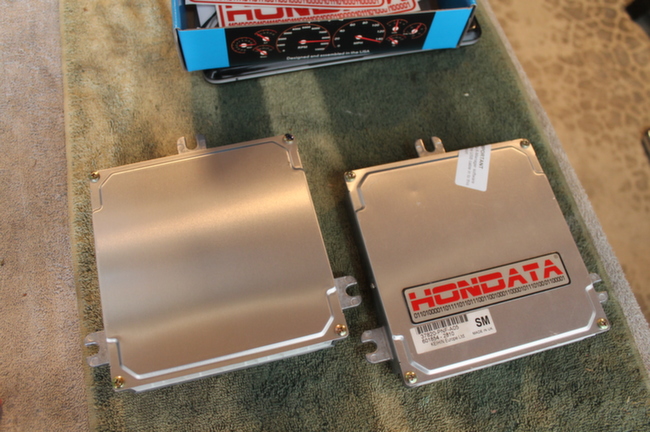

Once Hondata’s technician received my ECU, they tested that it functions properly. Then they open up the metal case and add their daughterboard to the main board. This new board is about a quarter the size of the main Honda board and fits snugly inside the case – allowing the ECU case cover to fit back on as it originally did. Hondata also cuts a small square opening into the side of the ECU case to allow for the USB port connection. As a final step, they closed the ECU back up, test it, and put a HONDATA sticker across the top of the case.

I also purchased a used laptop that runs Windows. I installed the free KManager software (http://www.hondata.com/downloads.html) from Hondata on it. The laptop and Hondata software will allow tuning of the K-PRO ECU via a USB cable. I reviewed Hondata’s installation and KManager tutorials online.

UNBOXING

A Fedex package arrived swiftly from Hondata. Inside the box:

* K-PRO ECU

* USB cable

* Serial input harness for data logging (I didn't need to hook this up for my needs)

* KManager software on CD (you can also download this online for free)

* Hondata license plate frame and stickers

* Printed materials and a note to relocated the ground strap on intake manifold

INSTALLATION

Installation was fairly straightforward. Here were my steps on my EP3 (your steps my be different):

1. Disconnect battery.

2. Remove the passenger side foot well trim panel. You should see the ECU. Carefully release and remove the harnesses leading to the ECU.

3. Bend or remove upper glove box “stoppers” to allow the glove box to swing completely open.

4. Use a 10mm socket to remove the 3 bolts holding the ECU in place. 1 bolt is behind the glove box, and 2 bolts can be removed from underneath the glove box.

5. You should now be able to remove the ECU.

6. Install your K-PRO ECU in place. Installation is reverse of the removal. Make sure the harnesses are securely clicked into place.

7. Before you close up the glove box, plug the USB cable into your K-PRO. I used a few zip ties to keep it from accidentally pulling out and let the rest of the USB cable rest inside the glove box.

8. Per the included note from Hondata, I relocated the battery ground strap from my intake manifold to the valve cover bolt. All that was required to do this was a 10mm socket. The existing ground strap is long enough for the relocation.

9. Reconnect the battery.

10. Turn the key to on (but do not start the engine).

11. Make sure your laptop has successfully installed KManager, and launch KManager. Then plug the USB cable into laptop. You can now upload one of the base maps provided by Hondata.

12. The next steps only apply if your K-PRO conversion was performed on a second hand ECU:

13. Using KManager, disable the immobilizer.

14. In order to have the immobilizer matched (progrmamed) to my ECU: I scheduled a service appointment at my local Honda dealer. My service advisor understood what a K-PRO is and what I was trying to accomplish. I drove to the dealer with the immobilizer disabled. Once there, I used my laptop to re-enable the immobilizer. This is an important step. If you don’t re-enable the immobilizer, the Honda tech’s equipment will not be able to locate and program your immobilizer.

FAQ

Q: Where can I get more information on the benefits and compatibility of the K-PRO system?

Hondata’s website has a lot of good information and is updated regularly:

http://www.hondata.com/kpro.html

http://hondata.com/media/kprotraining/k-propresentation.pdf

Q: Is the K-PRO only for heavily modified cars?

While the K-PRO conversion is well suited for turbo/ supercharger applications and K-series engine swaps, it can also help extract power from basic bolt-on parts such as a performance header, exhaust system and air intake.

Q: What is an immobilizer?

An immobilizer is an electronic security device installed by Honda that prevents the engine from starting unless the correctly paired/programmed key (with immobilizer chip) and ECU are present. It prevents a car from being stolen by a thief bringing his own generic key or ECU.

Q: Do I have to buy a 2nd ECU or can I just send the one in my car?

You can send the ECU that is currently in your car. There are pros and cons to doing that.

PROS: You won’t have to reprogram your immobilizer (assuming you want it enabled). And you can be certain the ECU is fully functional. There is also a cost savings since you won’t be buying a second ECU.

CONS: Your car will have a few days of down time since obviously your car will not be running while the ECU is being modified by Hondata. If you ever want to sell the K-Pro or return to a stock ECU, you will need to buy a stock ECU.

Hondata can also provide a brand new ECU at additional cost when you order.

Q: What is the big deal about buying from an authorized Hondata dealer?

Simply put, buying from an authorized Hondata dealer like King Motorsports protects you. Hondata has issued a warning that there are counterfeit K-PRO ECUs in circulation:

http://www.hondata.com/kpro_counterfeit.html

In 2014 a Florida man was charged by the FBI for having Hondata devices reverse engineered, then built in China and sold as authentic. He generated approximately $58k in income with his scam, so you can only imagine how many fake Hondata devices he put into circulation.

Hondata also warns of a scammer from Texas named Daniel Sanchez who claims to be authorized to sell on behalf of Hondata but is not a Hondata dealer. He has also spread some misinformation about Hondata. More info:

http://www.hondata.com/sehablaauction.html

Q: What’s the difference between a Hondata Reflash and a K-PRO?

A Reflash is a reprogramming of your ECU by Hondata. Rather than installing a full daughter board into your ECU case, Hondata reprograms your ECU directly to extract more power with pre-determined changes such as altered cam timing and optimized fuel settings. The cost is significantly less than the full K-PRO conversion, but is not customizable for your car’s specific mods.

More info about the Reflash:

http://www.hondata.com/reflash.html

You can always upgrade from a Reflash to the full K-PRO at a later date.

Q: Can I upgrade to a newer version of K-PRO?

Hondata has been very good about consistently updating the K-PRO hardware and software systems. While the software updates are free, the hardware updates are not. Hondata has a program that will allow you to purchase an upgraded K-PRO conversion by sending in your working, older K-PRO ECU.

Q: What kind of laptop do I need to run KManager?

Right now nearly any Windows laptop or netbook will work, including older ones running Windows Vista or newer. A desktop computer will work too, but has obvious portability limitations. A Mac OS will work as well if you have a compatible Windows emulator. Some have even used certain models of the Windows Surface tablets (the ones that run the full Windows 8, not Windows 8 RT). I was able to buy a used Acer netbook from our company’s IT department for about $50. KManager does not take very much CPU power to run, so older laptops will work just fine so long as they meet the software’s minimum operating requirements.

***

King Motorsports is an authorized Hondata dealer. Buy with confidence online or by phone at (262) 522-7558:

http://www.kingmotorsports.com/advsearch.aspx?SearchTerm=hondata

***

VISUAL COMPARISON

Here is a side-by-side comparison of a stock ECU (left) and the K-PRO conversion (right):