We've had so many pictures to share of our 4th gen Honda Prelude race car project (dubbed "San Pedro") that we've decided it's high time to start a new blog post! Welcome to "Re-inventing 'San Pedro' Part 2"!

Update 1/18/2013:

This week we have been working on building the plug from which the mold for the front air dam will be made. The airdam will provide a platform to mount the front splitter once completed. Here we are roughing out the foam core to the basic shape we are looking for.

Once the basic shape has been roughed out, Bondo is applied and sanded into a finished shape. This is a very time consuming process as the entire air dam has to be symmetric -- with a perfect surface finish. Up next, building the mold from this plug and making finished pieces out of carbon fiber! Stay tuned.....

Update 1/24/2013:

Work continues on the front airdam plug. After numerous coats of Bondo and shaping, we are getting close to a finalized shape. Next step is several applications of high build primer and sanding to make the surface of the airdam plug absolutely perfect with no pin holes or sanding marks. This is roughly what the airdam it will look like when attached to the front bumper.

Update 1/30/2013:

We have now completed the plug for the front airdam mold. Before the mold is made from this plug, it will be liberally coated with wax and then with a mold release agent so the fiberglass used in making the mold does not stick to the plug.

Here is an example of what the final mold looks like. The molds are designed to have great strength so there is no potential for any dimension of the final part to change during the lay up process.

The next step in producing the airdam for San Pedro is vacuum bag moulding.

Vacuum bag moulding uses a flexible film to enclose the part and seal it from outside air. A vacuum is then drawn on the vacuum bag and atmospheric pressure compresses the part during the cure process. Vacuum bag material is available in a tube shape or a sheet of material. When a tube shaped bag is used, the entire part can be enclosed within the bag. When using sheet bagging materials, the edges of the vacuum bag are sealed against the edges of the mould surface to enclose the part against an air-tight mould. When bagged in this way, the lower mold is a rigid structure and the upper surface of the part is formed by the flexible membrane vacuum bag. The flexible membrane can be a reusable silicone material or an extruded polymer film. After sealing the part inside the vacuum bag, a vacuum is drawn on the part (and held) during cure. This process can be performed at either ambient or elevated temperature with ambient atmospheric pressure acting upon the vacuum bag. A vacuum pump is typically used to draw a vacuum. An economical method of drawing a vacuum is with a venturi vacuum and air compressor.

A vacuum bag is a bag made of strong rubber-coated fabric or a polymer film used to compress the part during a cure or hardening process. In some applications the bag encloses the entire material, or in other applications a mold is used to form one face of the laminate with the bag being a single layer to seal to the outer edge of the mold face. When using a tube shaped bag, the ends of the bag are sealed and the air is drawn out of the bag through a nipple using a vacuum pump. As a result, uniform pressure approaching one atmosphere is applied to the surfaces of the object inside the bag, holding parts together while the adhesive cures. The entire bag may be placed in a temperature-controlled oven, oil bath or water bath and gently heated to accelerate curing.

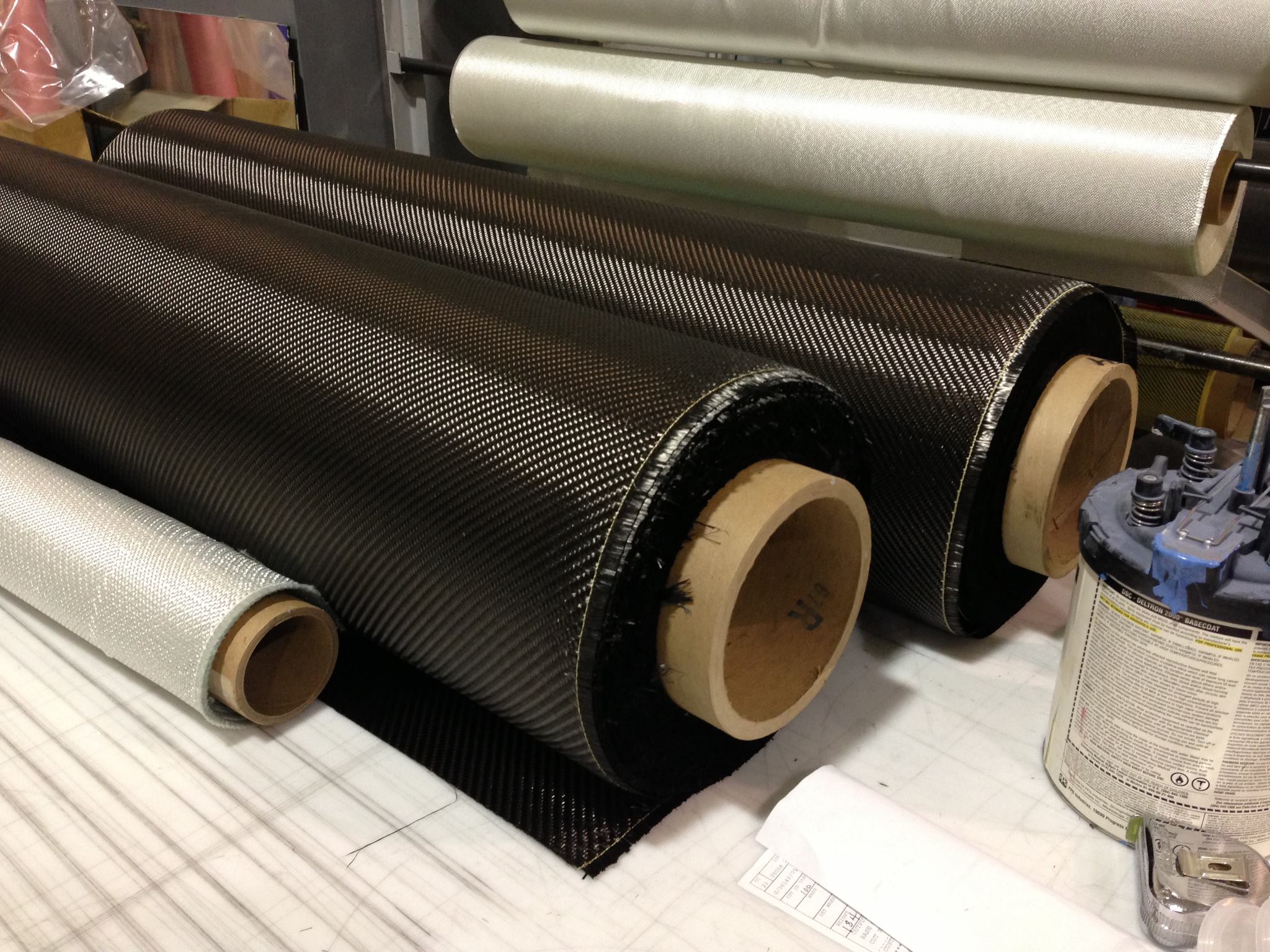

Here are rolls of carbon fiber material that will be used to make the final airdam.

Daytona Red race cars have taken over the shop today!

Update 2/26/2013:

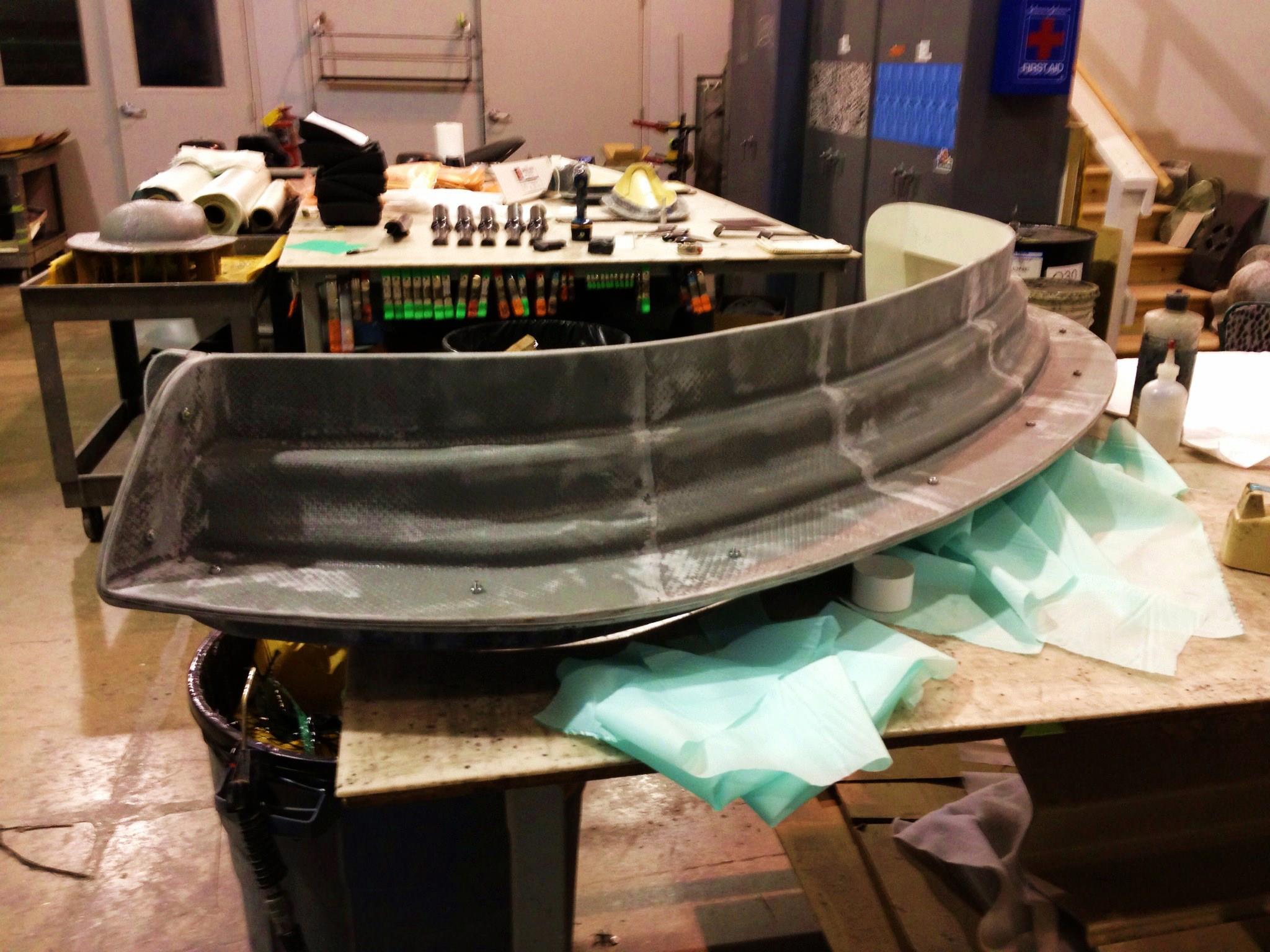

San Pedro update! The mold for the front air dam has been completed. Notice the robust construction of the mold to insure there is no chance of a core shift. Pictured is the backside of the mold. The upper and lower half are bolted together and then unbolted to release the final part.

Here is the inside of the front air dam mold for San Pedro. The surface finish has to be glass smooth as your finished part will pick up any imperfections.

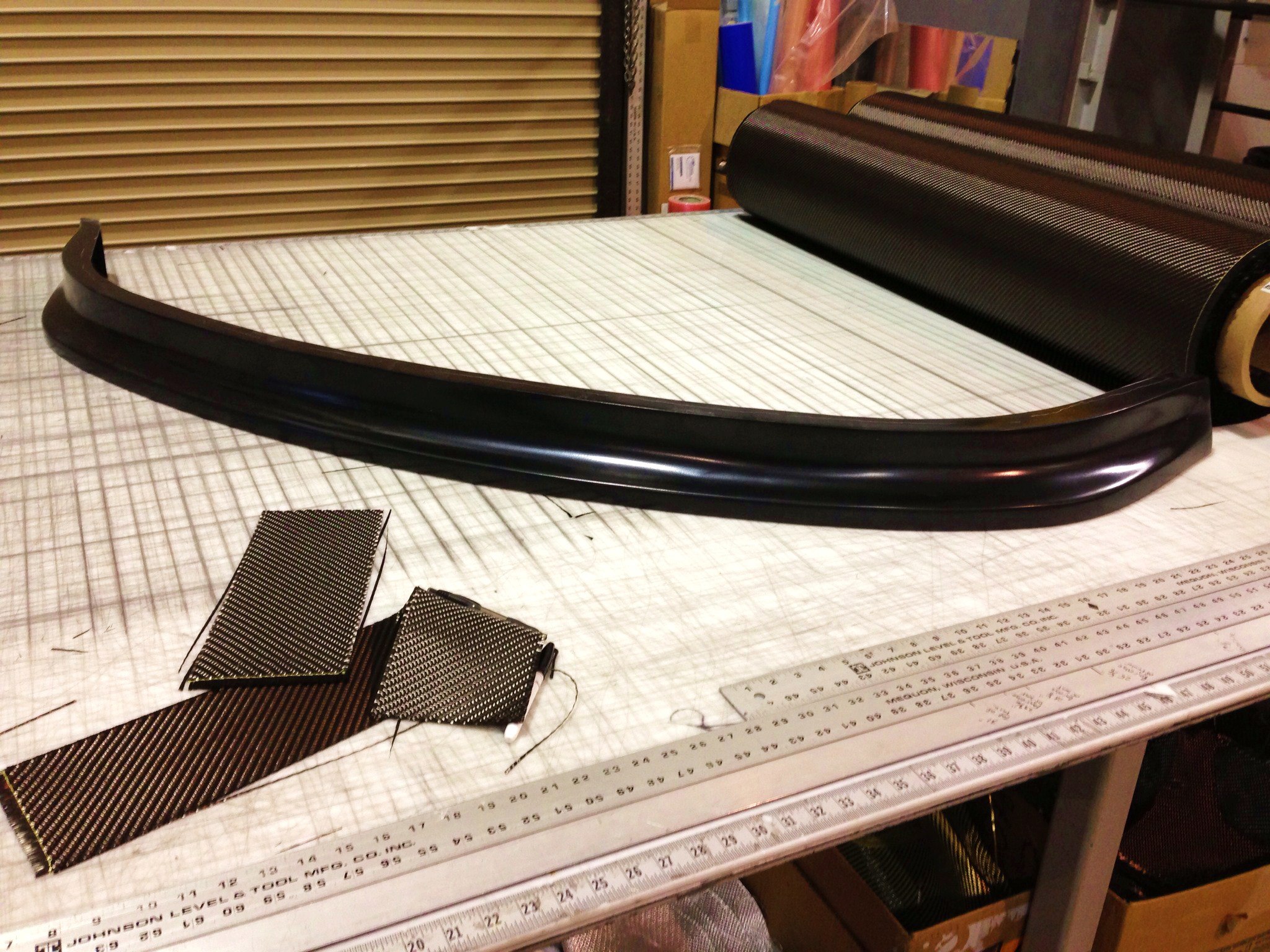

A look at the first carbon fiber air dam out of the mold for San Pedro. Next up fitting to the car and measuring for the splitter plank....

Update 3/26/2013:

The front splitter/airdam is now complete and mounted. Next up building shrouding for the radiator, brake ducts and an airbox...

Update 4/3/2013:

In the shop today: TIG welding the aluminum airbox for San Pedro.

Update 4/4/2013:

Yesterday we bid a fond farewell to San Pedro. Next week we'll be testing San Pedro at an "unidentified" race track working various chassis setups. Here are a few photos before San Pedro was loaded up to head to its new home.

San Pedro basking in the sunlight after a winter makeover...

Detail shot of the front airdam/splitter profile. Lot's of downforce to be expected. How much? We shall soon see :)

All that's needed is the spacer between the seat and steering wheel :)