King Motorsports is a leader in building Honda engines that balance power and reliability, and we've been doing it for nearly 30 years!

Read our staff interviews with Mike Lindquist and Chad LeBeau for a glimpse into the care we put into builds.

Here are some of the motors we've been working on recently...

This is a B Series cylinder head we are putting the finishing touches on. We're doing a King Motorsports Ultra cylinder head prep which will be shipped out to its new home in Brazil shortly!

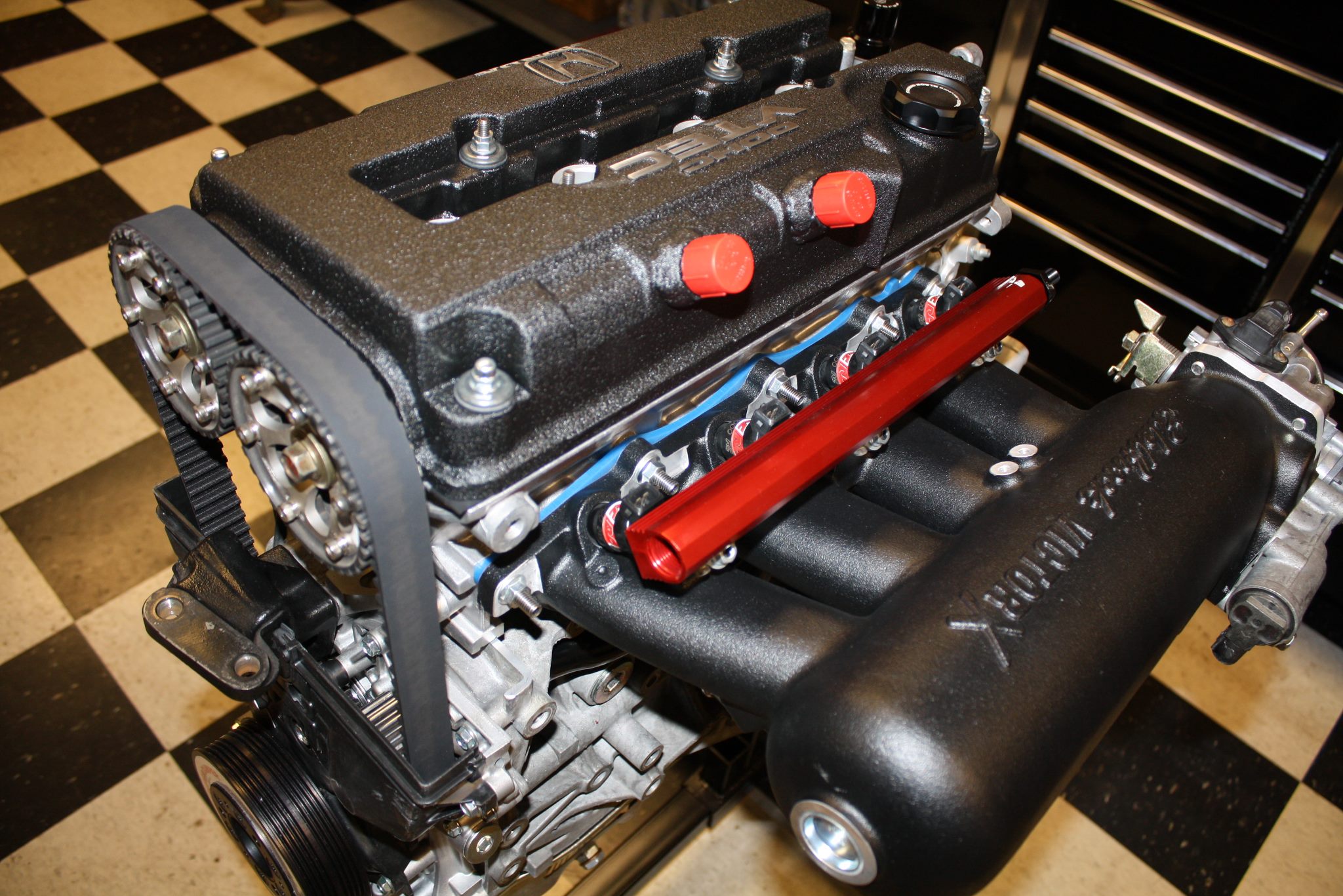

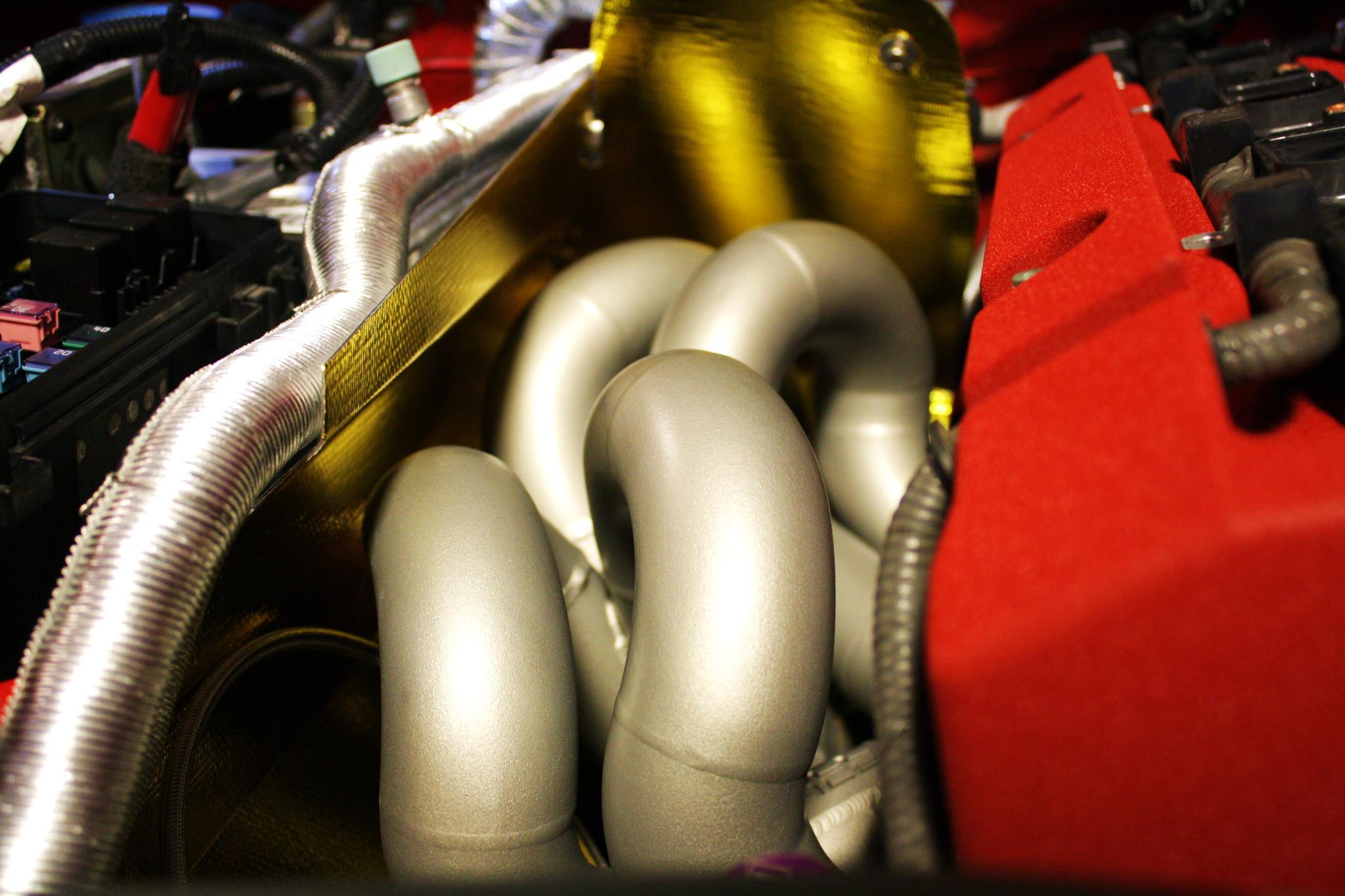

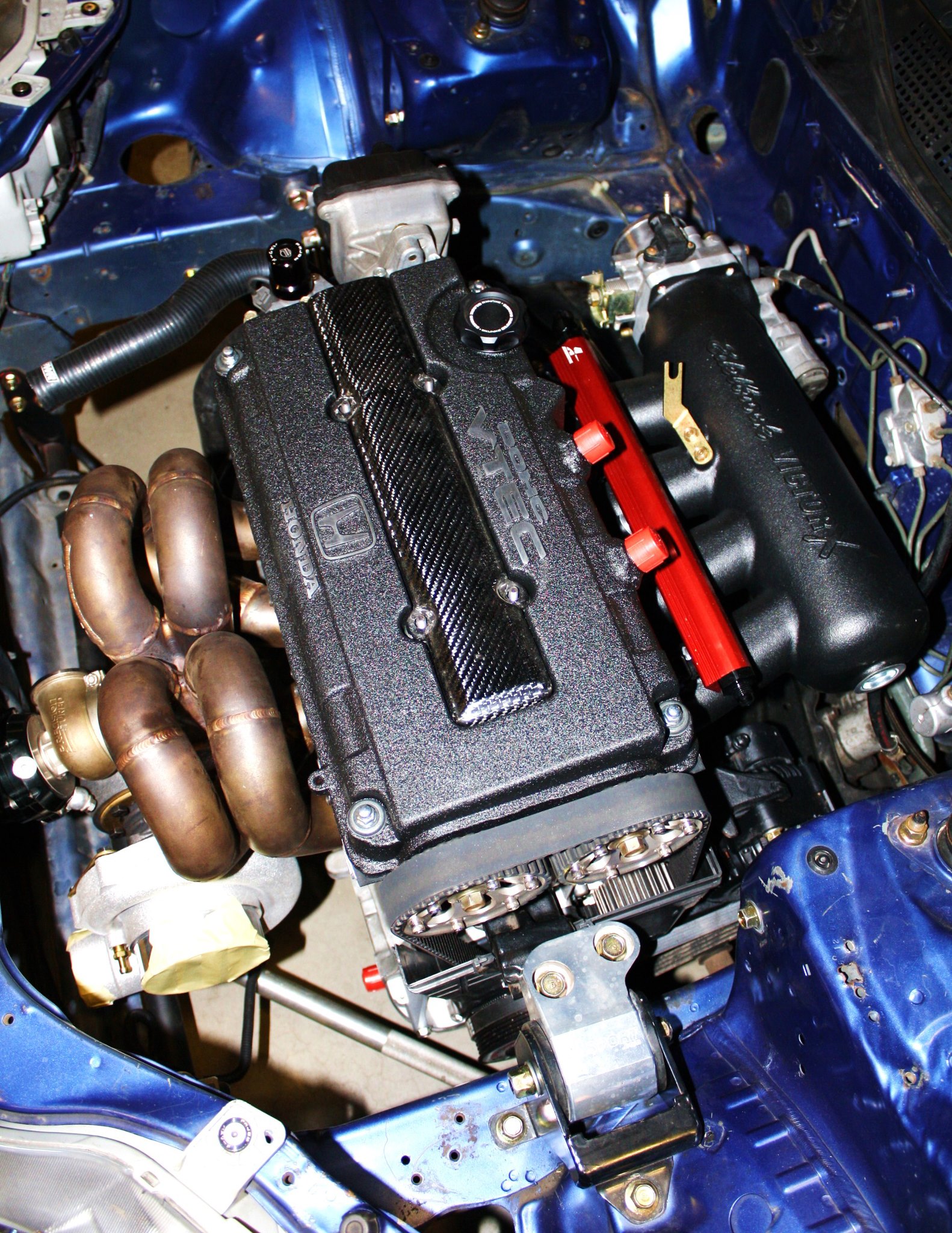

This is a 85 x 89 KMS B Series Turbo engine just finished up for a customer. Ready to install!

Here's another angle for the newly-completed King Motorsports Turbo B. Note the KMS valve cover venting with fresh powder coating.

The finishing touch on every King Motorsports prepared engine is this uniquely-numbered authentication tag. All engines we prep are serialized and all build specs achieved.

Here is an unclothed 87.2 x 81.5 B Series turbo build in the engine room waiting for final dressing:

The Turbo B Series long block build ... now fully dressed and awaiting installation.

Update 2/14/2013:

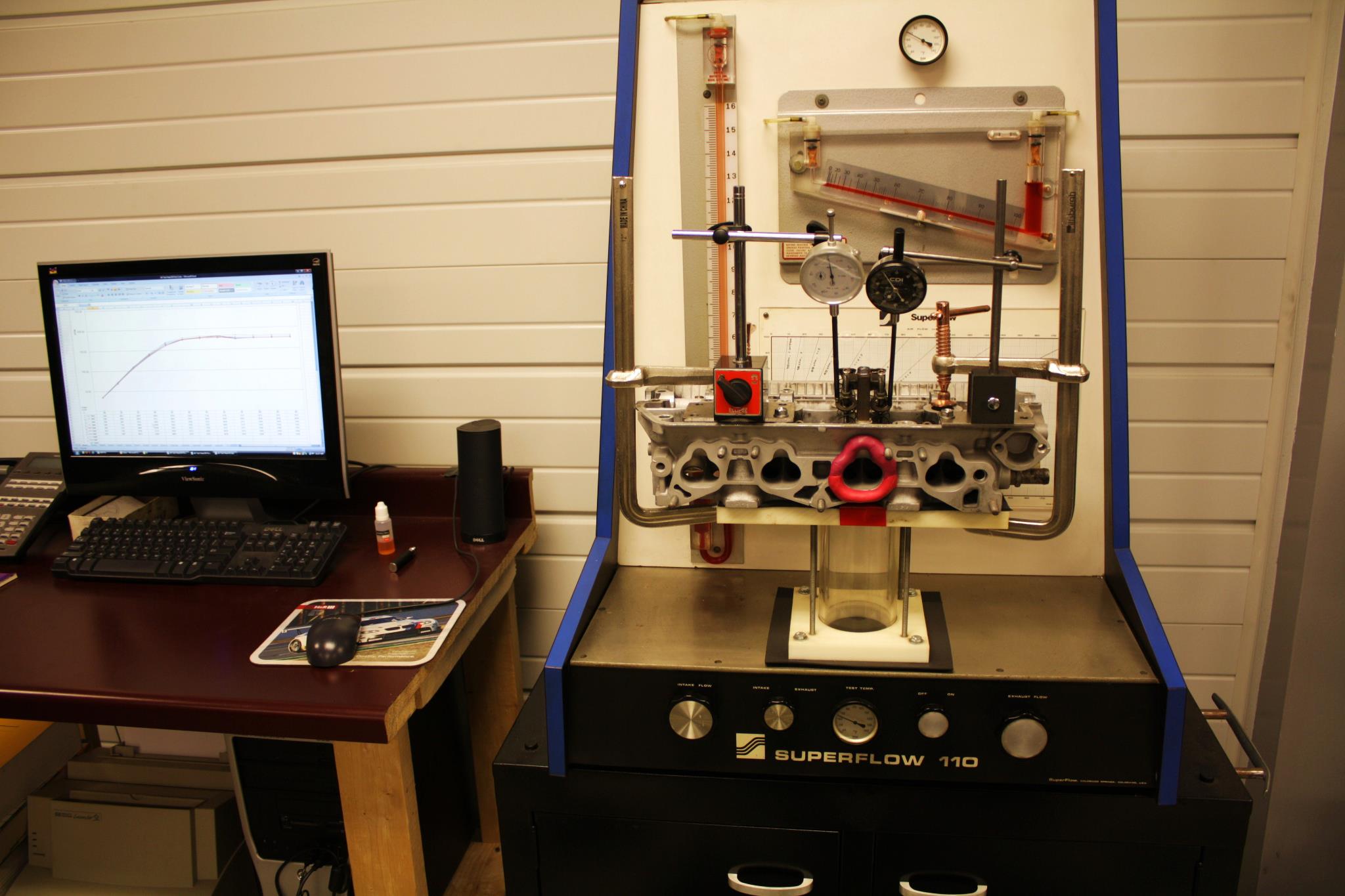

This week on our Flow Bench we are dialing in a customer's cylinder head. There is no substitute for real world numbers-- no guesswork here....

http://www.kingmotorsports.com/c-231-cnc-heads-valve-jobs-head-porting-milling.aspx

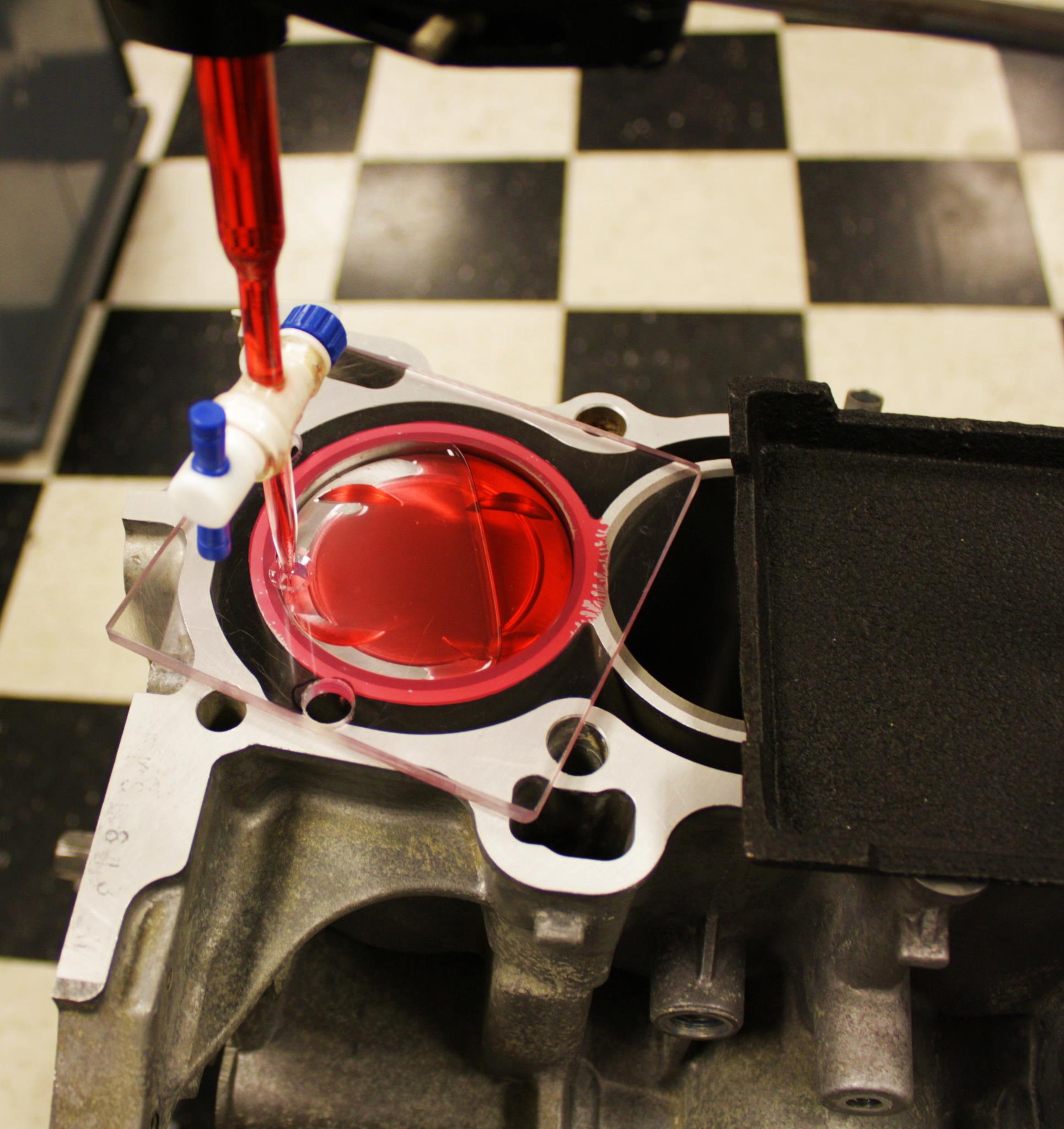

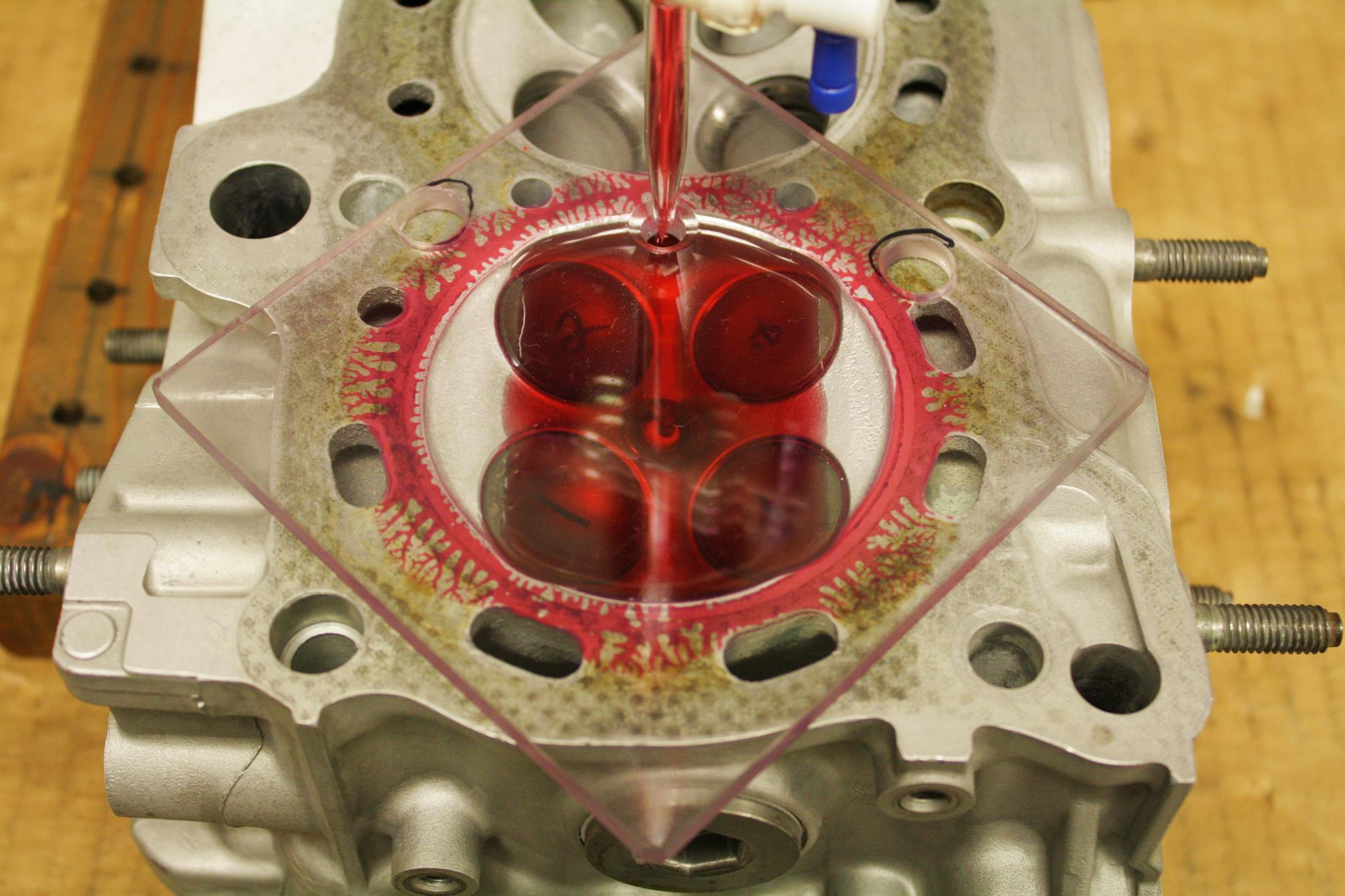

King Motorsports factoid: In the over 30+ years we've been building engines, we have found the majority of advertised piston dome values to be off. The only way to calculate true compression is to CC the cylinder head and measure the piston dome volume as shown below. This is important step is part of EVERY engine build we do at King Motorsports.

http://www.kingmotorsports.com/c-206-engine-building.aspx

Here we are CC'ing a cylinder head. Once we have the volume of the combustion chamber, combined with the volume of the piston dome plus a little math- we arrive at our compression ratio. Oh- and don't forget to measure the valve to piston clearance, but that's another chapter :)

http://www.kingmotorsports.com/c-231-cnc-heads-valve-jobs-head-porting-milling.aspx

Just finished up the D series race engine. Next up some header and exhaust development on the dyno, then off to hopefully win another SCCA championship :)

http://www.kingmotorsports.com/c-194-engine.aspx

Update 2/21/2013:

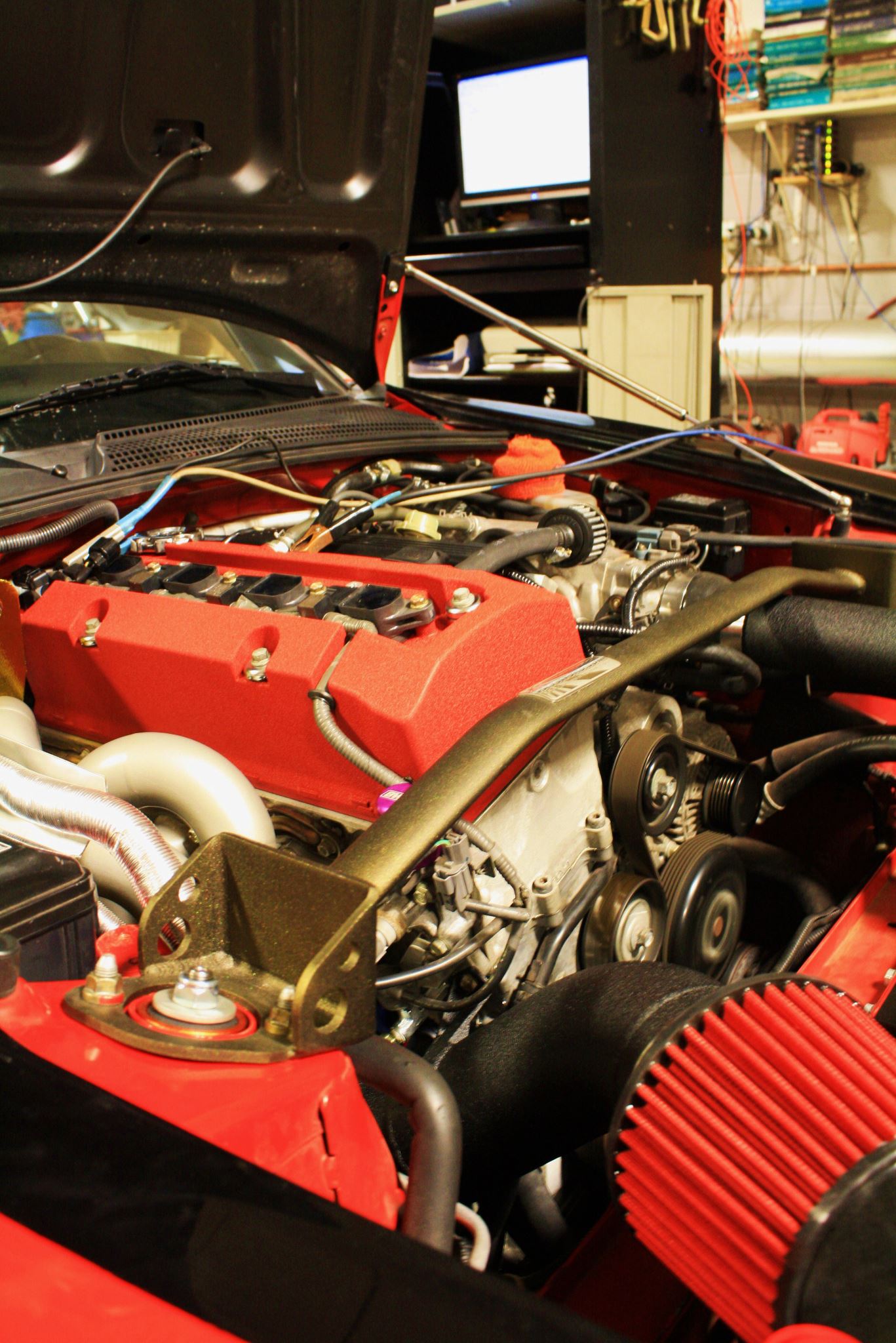

Full Race Turbo AP1 S2000 project just burst to life in the shop! Checking vitals then on to the dyno for tuning.....

http://www.kingmotorsports.com/c-173-dyno-tuning.aspx

Making sweet AP1 turbo noise on the dyno.....

Update: 2/28/2013

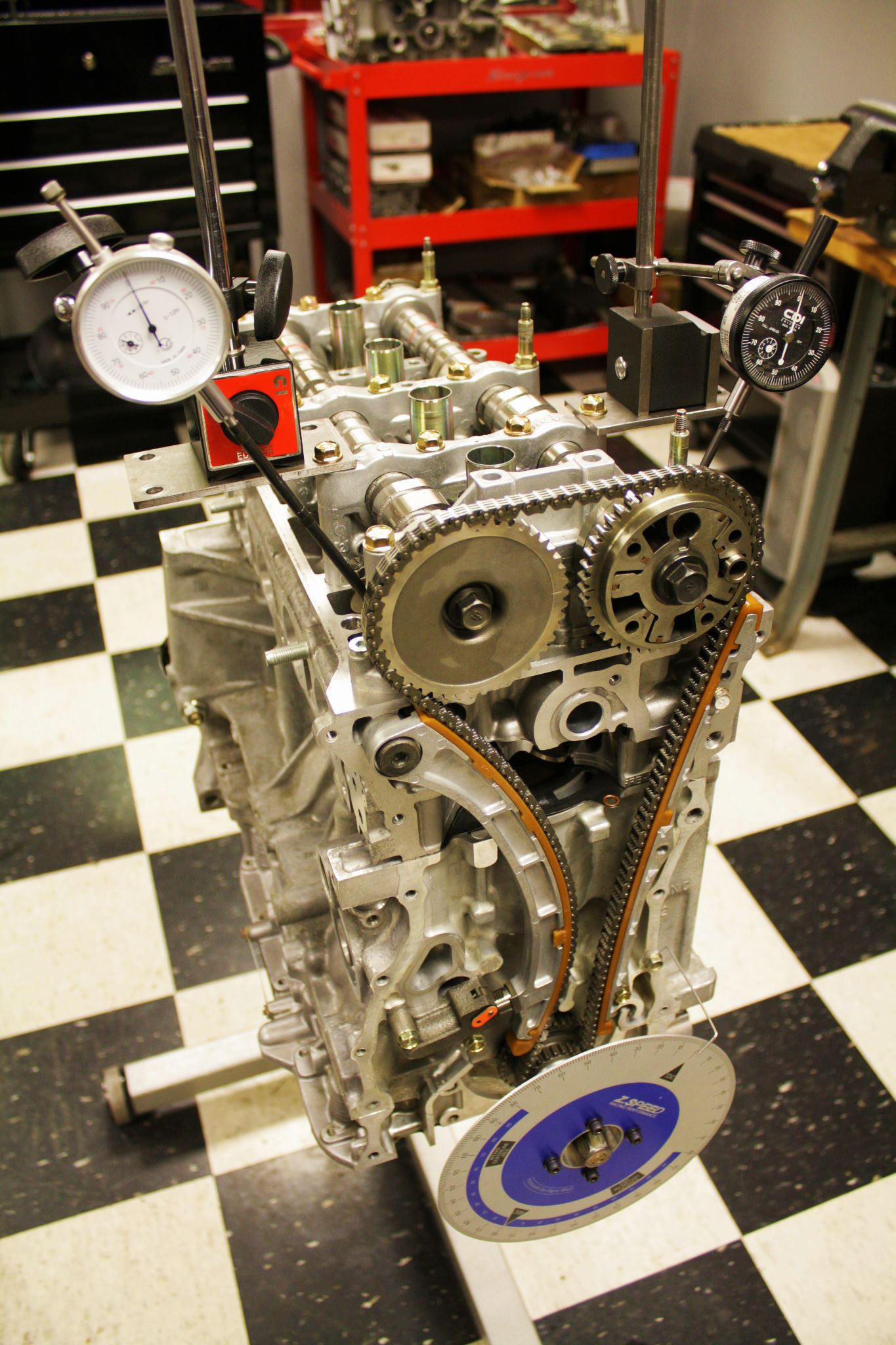

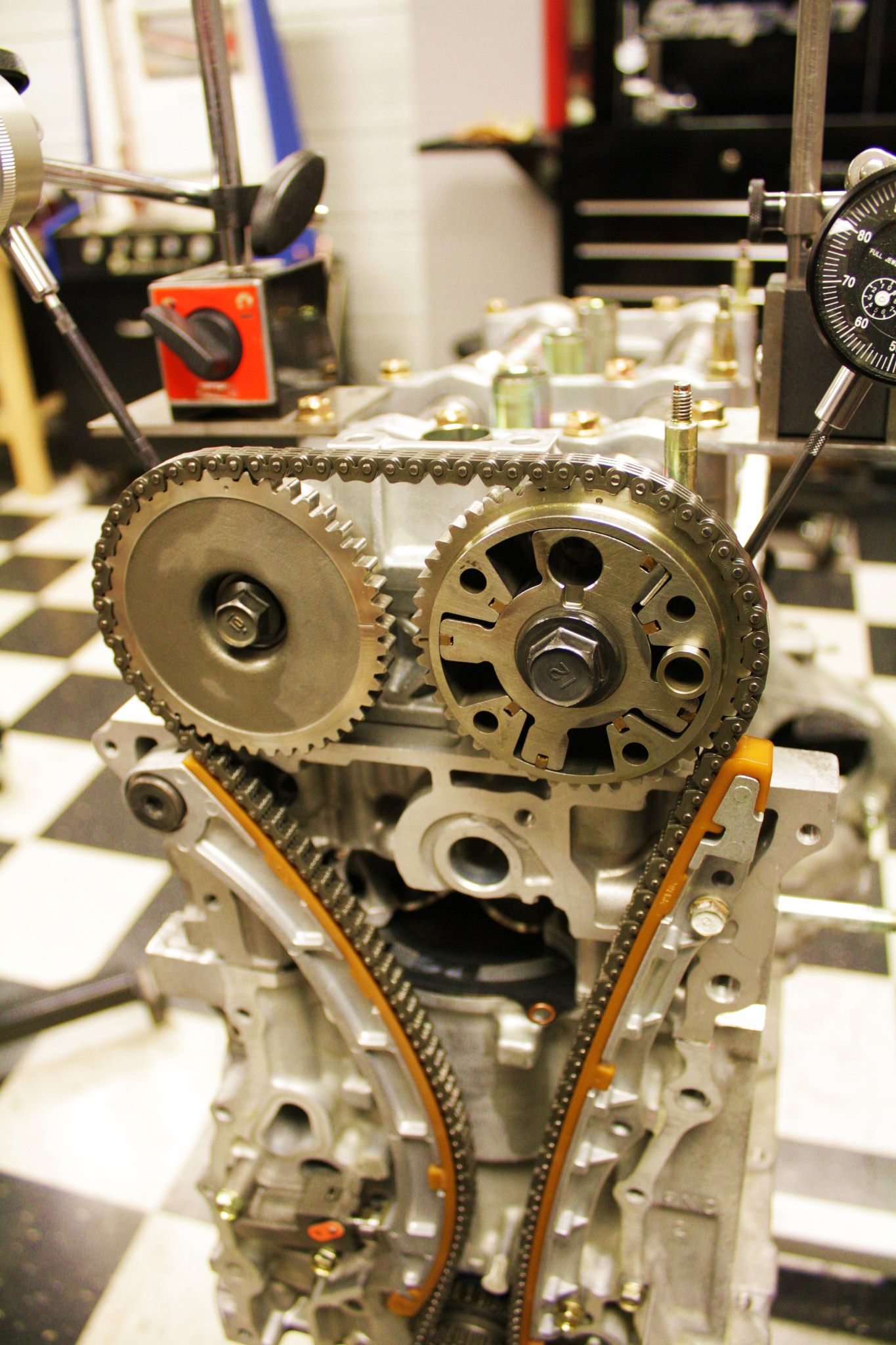

This morning in the engine room we are checking piston to valve clearance on a set of Kelford Stage 2 cams on a K20A bottom engine. We use a cutway cylinder head so we can actually see and measure the clearances.

http://www.kingmotorsports.com/engine_building.aspx

Here's a look at what you can see with the cutaway cylinder head..

The stock K20 VTC cam gear gives 50 degrees of advance. When installing a higher lift camshaft set there can be piston to valve clearance issues at maximum advance. Previously the only way to limit the VTC advance was to use a TSX VTC gear which is 25 degrees. Through our dyno development program on the K20 engine we saw 25 degrees advance is not enough to make optimum low/mid range power. Using this knowledge we designed a new King Motorsports VTC cam gear that limits the advance to 30, 35 or 40 degrees. Now you can have the not only great top end power with a solid mid range to match!

http://www.kingmotorsports.com/p-4294-kms-k-series-adjustable-cam-gears.aspx

One of the current projects in the shop is this EK Turbo coupe. We just finished up the engine, now are working on the fabricating the intercooler, intercooler piping, air filter setup, dump tube and exhaust system- then onto the dyno for some tuning!

http://www.kingmotorsports.com/c-173-dyno-tuning.aspx

Update: 3/3/2013

After mapping out where we are running the intercooler piping, etc., we are hard at work fabricating a battery box for a lightweight battery on the our Turbo EK Civic Coupe project.

http://www.kingmotorsports.com/c-242-fabrication.aspx

Work continues on the Turbo EK Coupe project in the shop. Here we begin wiring the Hondata Coil on Plug retrofit kit.

http://www.kingmotorsports.com/p-4122-hondata-coil-packcoil-on-plug-retrofit.aspx

In the fab shop today- just finishing up a King Motorsports prepped B series intake for a client.

http://www.kingmotorsports.com/p-4048-king-porting-service-edelbrock-performer-x-intake-manifold-b-series.aspx

Update 4/5/2013:

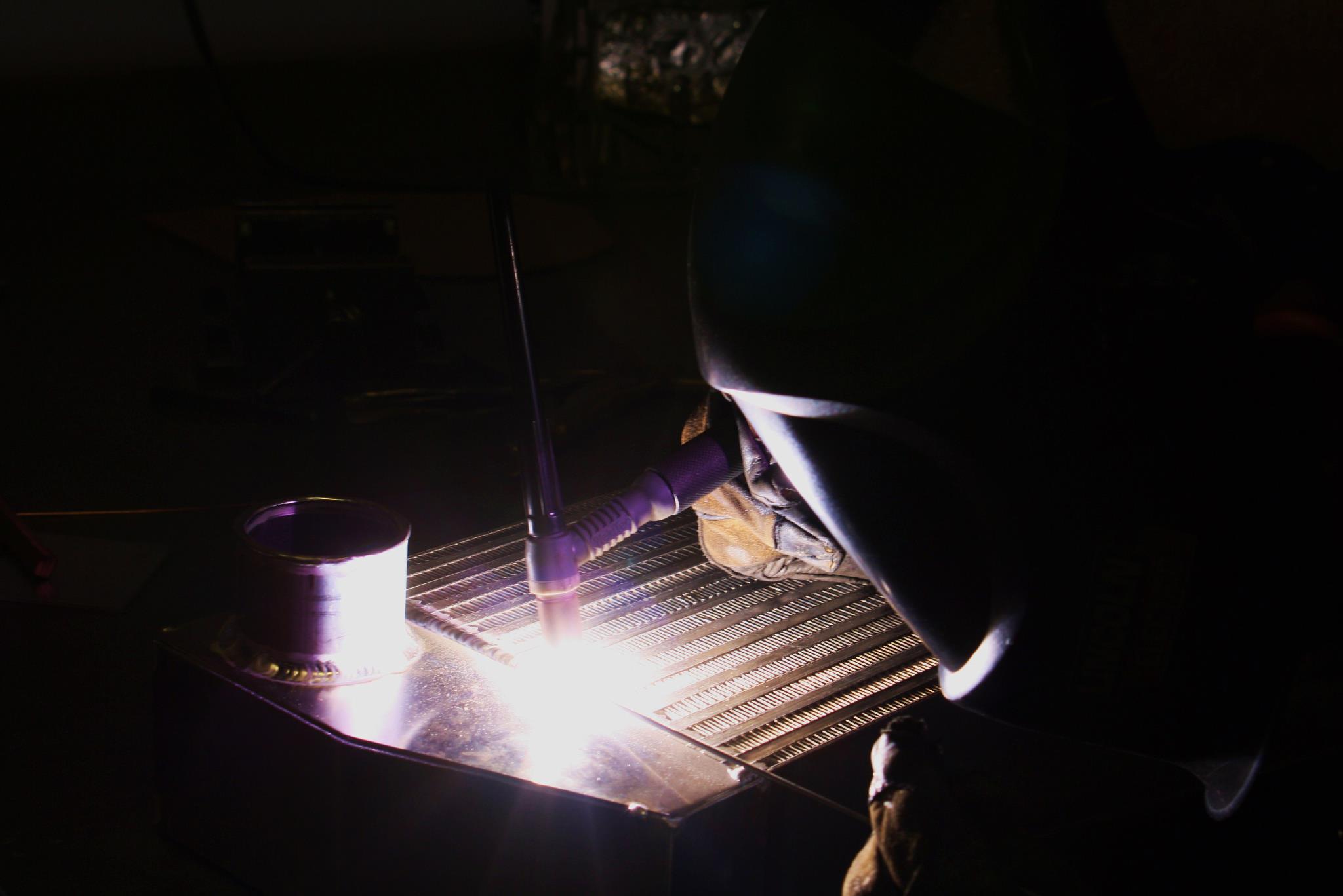

In the shop this morning- fabricating intercooler tanks for a B series turbo build.

http://www.kingmotorsports.com/c-242-fabrication.aspx

We just completed this H22 build. King Motorsports cylinder head prep, sleeved 13:1 with Skunk Pro 3 cams and a Euro R intake. Installation and dyno work next!

http://www.kingmotorsports.com/c-194-engine.aspx