Soichiro Honda was driven by a lifetime of passion for all things mechanical. That passion led him to become a skilled mechanic, driving the creation of the company we know and love today. Along the way, Soichiro’s enthusiasm for speed and adventure never took him far from racing cars and motorcycles.

It’s no accident that Soichiro’s love of motorcycles, horsepower and engineering is shared by one of the best Honda engine builders in the world: King’s own Chad LeBeau.

I caught up with Chad recently to talk engine building, motorcycle racing and the beer he would have had with Soichiro Honda.

What do you do at King Motorsports?

My title is Engine Builder. In the past, I also did fabrication (such as roll cages), but we've since hired other people to do that so I could focus on engine building. I used to do a little of everything. Compared to 12 years ago when I first started, we have so much engine work to do now that I primarily focus on engine work. But I can do pretty much everything except for tuning, which is Tim's area of expertise. But we can both do roll cage work and any type of fabrication, machining, etc.

For the most part, for the last several years I've been doing engine work.

I build the engines. Sometimes I'll install the engine, but usually someone else installs the engine and Tim will then tune it on the dyno. I'll do the cylinder head work, all the blueprinting and balancing, and assembly. Then it's up to Tim to make horsepower. If it doesn't make horsepower as it should, I just blame it on Tim. (laughs)

As far as tuning goes, we work with Hondata for engine management. We work with the AEM units too. It's basically putting the engine on the dyno, hooking it up to a wideband O2 so you can get the air-fuel, and making adjustments on timing, air-fuel, and VTEC engagement. With the K series, we also have cam advance on the intake, which is a whole other variable when it comes to tuning. It's a lot of dyno runs, then fine tuning fuel, ignition and stuff like that.

How did you first get connected with King Motorsports?

Back around 1999, I was a customer when the shop was located in Sullivan, WI. I was out there several times picking up parts. I got to know King’s President and CEO Scott, and he mentioned he was looking for an engine builder (who could also be a fabricator). I told him “Well that's what I'm doing now.” So we set up an interview, and it all worked out from there.

What drew you to Hondas?

I worked at a Harley-Davidson shop prior to King Motorsports. I was into motorcycles and motorcycle racing. I raced Honda bikes, but I knew a bunch of guys who raced both bikes and cars. Before the Harley-Davidson shop, I was working at a Ford dealership.

One of the salesmen from Ford moved over to a Harley-Davidson dealership. He got me a job at Harley-Davidson.

I've always been a Honda guy. Motorcycle racing is where I got started on Hondas, transferring my engine and racing experience over to cars. The more I learned, the more I saw just how far ahead Honda was ahead of the other guys, especially in their engine program. Back in the early '90s, just when I was getting into motorcycles, it seemed like Honda was way ahead of everyone -- both motorcycles and cars.

Did you have any formal training?

I took every shop class in high school. I took auto, welding, machine shop, electronics, you name it. I also went to UTI Auto Tech School, but left after 3 months. I already had a job at the Ford dealership, where I was able to learn on the job.

I am fortunate to have worked at places with knowledgeable people. The Harley-Davidson dealership was very involved in both motorcycle road and drag racing. They are just down the street from us. We did really involved engine work, they have smart guys that work there, so I learned cylinder head flow and other skills. I also learned from people at King. I’m fortunate to be around smart people I can ask questions of.

So what was your interview with King like?

It was a typical interview. We reviewed my background and work at Harley-Davidson. I told them I could weld, fabricate, machine, etc.

But did Scott ask you to build an engine blindfolded, ninja-style?

No, ha ha.

What is your background in racing?

I raced in CCS (Championship Club Series), which is like the SCCA, except it’s for motorcycles. It’s road racing at a regional level. I always raced the Honda CBR600F2. I did that for 2 years before I went broke and couldn't go any further.

What project cars have you owned over the years?

Just my '90 Integra LS, which is the car I was buying parts for from King. I still have the car. I do track events with it now. That's my project and hobby car.

Although I'm not the original owner, my favorite mod was putting Hoosier racing tires on it. (laughs)

I’ve had several motors in my Integra over the years. Currently it has B17 VTEC from a ‘92-93 GSR. It makes about 200-ish WHP, not bad for a naturally aspirated motor. I'm building out a different motor for it right now, a 92 stroke motor. Hopefully I’ll get 240-250 WHP out of that, we'll see.

What categories of engine building are you involved in?

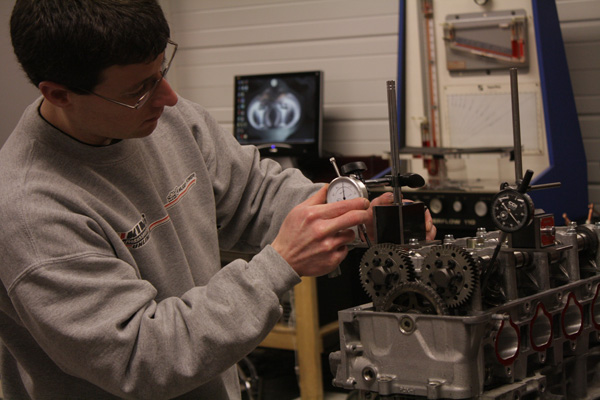

At King, we do it all. That includes working on the bottom end, measuring all the bearing clearances, and balancing the crank, rods and pistons. We bore and hone it. A lot of the work is in the cylinder heads, as far as doing the porting and the valve job. We also run it on the flow bench, trying different things with the porting and valve job to increase flow. Once all of that's done, I do a mock up assembly and check the piston and valve clearances, degree the cams in, etc. Once I make sure all the clearances are right, I go back and clean everything, re-assemble it, then do a final check on the cam timing. That’s pretty much the short version. It's a lot of measuring and checking clearances, which can be a time consuming process. By the time you're done, you've disassembled and assembled things 3 or 4 times.

I've seen your work area, and it resembled an immaculately clean laboratory!

Yeah, any nicer shop is going to have a separate clean room for doing all the final assembly work. It's too hard to have all that stuff out in the open in the shop. With all the machining stuff, and grinding cylinder heads, I'm making quite a mess, so we have to keep that stuff separated otherwise it's almost impossible to keep it clean.

What does it take to have a good reputation as an engine builder?

I’d say it’s a balanced combination of making an engine that a) gets good HP numbers and b) performs reliably.

What is the most interesting part of engine building for you?

I definitely like the cylinder head, porting and valve jobs. I like working on our flow bench, constantly trying to make the cylinder heads better, and the valve jobs better. I like the challenge of getting more flow out of a motor. I definitely found that how the engine performs on the flow bench relates directly to how it will perform on our dyno. If we get an improvement on the flow bench, we almost always see an improvement on the dyno too.

What is a flow bench?

It's a machine, basically a big vacuum cleaner, if you will. It has several big vacuum motors in it, and it measures the head, the lifts at the valve ... simulating the moment when the cam opens the valve. Our flow bench measures air flow at each lift and the flow of the cylinder head at all the different lifts at the valve.

So it's like a simulator of the engine movements without the inherent risks of having gas exploding?

Right. Basically the way you increase a motor’s power is to increase the air flow both in and out. The quicker you can get it in and the quicker you can get it out, the better. Compression plays into that too. The higher the compression ratio, the more it compresses, the more power it makes. The flow bench can help me determine how effective the porting and the valve job were.

How many customers do you have that are local vs. ones that ship motors to you (such as from outside the US)?

We have a fair mix, about even across the board... Local Wisconsin guys as well as from Northern Illinois and Chicago, but we have plenty from other states as well as from around the world!

We also have customers that ship us their engines from overseas – they just put them on a pallet and crate them up.. We use Mike's old drag car as a K series motor tester, and we have another car for the B series motors.

Do you have a favorite engine or swap?

Hmm, I don't really have a favorite. But we do more B series than anything else.

That said, I like doing the K series – they’re interesting motors. They have roller rockers, an adjustable intake cam, and the advance on the intake cam is controlled by the ECU, so you can control the cam timing on the intake cam, which is pretty neat. It’s a lot more work for Tim to tune though. There are a few things they've improved on over the B series engine: the bottom ends are a little stronger; the way the main bearings hold to the block as one big “girdle” if you will. All the main bearings are connected to each other in one big piece of aluminum, so the bottom end is pretty stout. The cylinder heads flow better, there are bigger valves, bigger ports. It's a little better in terms of wear on the cam shafts.

The B series are definitely our core. We have the most R&D done for B series cylinder work, valve jobs, custom intake manifolds, headers, etc.

How much do you get involved with R&D?

We’re doing a little R&D with every engine build. I'm always working to get the heads to flow a little more, trying new things... I've got plenty of scrap cylinder heads that I'll experiment with to find new ways to port and valve to increase flow in the flow bench.

With the B series we've done quite a bit of R&D on intake manifolds, cutting them apart, porting, and then welding them back together; even making our own from scratch. We'll take the flange off a stock manifold and go from there. Some of the aftermarket and Edelbrock ones are pretty good. We modify them and keep trying different things. It's always a learning process. We never get to a point where we're like "Ok, we've got the end-all best solution now." Instead, every month we see new ways improve flow. It's kind of a never-ending pursuit. We're always striving to extract more horsepower.

How long do typical builds take?

They typically a month in terms of duration, accounting for getting parts in and taking parts to the machine shop (we have a machine shop that does all of our boring, honing and balancing). So by the time we get all the parts in and get the cylinder head worked on it's about a month to a month and a half.

What do you think about the industry’s shift towards greener power plants? What do you think of the CR-Z?

I personally only have modest experience with the CR-Z. King did the Mugen suspension on one and had it on the dyno, but I haven’t yet had the chance to take the engine apart to see how the engine's electrical assist works. I know when the CR-Z is wide open and the electrical assist is working, it's draining the battery. You can only do that for so long and then it's got to recharge itself.

So the first thing that came to mind for me is that the stock electrical assist might not be practical at a track event because you'd probably get half a lap in and then the battery power might start to drain. So I don't know how well the electrical assist would work on the track.

It's sort of like the technology in F1 cars. They have an electrical assist called the Kinetic Energy Recovery System (KERS). Drivers are only able to use the system a couple of times per lap. So they’re incorporating a similar technology into F1.

It would be nice if the CR-Z had a bit better power plant to start with. Like if it had a K series motor. Obviously the CR-Z is more about fuel economy then high performance, but it seems Honda is trying to feel out a balance. The CR-Z looks great. I'd love to see Honda try to make a similar style hybrid out of a Civic Si.

It's a little discouraging to see Honda get rid of the NSX, then the RSX and now the S2000 -- it seems like Honda is getting away from performance cars a little bit. So I'm looking forward to seeing what Honda comes up with to replace those models. In terms of performance platforms, right now we just have the Civic Si and TSX.

What makes King Motorsports different from other shops?

I don't think there are a lot of shops that do as much as we can. For example, we do roll cages, engine work, development, chassis dyno, and all the rest of the heavy lifting that goes into preparing race-spec vehicles. There aren't a lot of shops that can offer all those things.

We're well-rounded. We're not just a place to come get your car tuned or buy parts. We can build your car from the ground up: fabrication, engine work, tuning, suspension, brakes -- everything you need to build a race car. So if you’re looking to build a race car, you don't have to take your car to multiple shops. We can do everything right here; We're a one-stop shop.

What can you tell me about King’s long-standing relationship with Mugen?

I don't personally get into the part sales. But I can say it was definitely nice when we were racing the World Challenge series and we'd have a couple of guys from Mugen come out from Japan to support us at the races. We'd hang out with them and talk shop. I got to spend time with one of Mugen's engine guys, asking questions and sharing stories.

If you could go back in time to meet the founder of Honda, what would you do?

I'd have a million engine questions to ask him. It'd be cool to see his facilities, see his machines and what makes his shop run. I'd ask him about his cylinder head designs, the differences in bore and stroke and rod ratio. Stuff like that.

So you'd buy him a beer and pick his brain for a while?

Right! I wouldn't know where to start!

I might ask why they never came out with a V8 NSX, or an inline six S2000. Honda has always pursued the most power-per displacement engines, but they never seem to make a big displacement motor. Their focus is getting the most power out of smaller motors. Man it would be cool if they had a V8 NSX ... or that inline six S2000. Seeing as how they get so much out of those smaller motors, I can only imagine what they'd do with larger motors!

What do you think the next 30 years will be like for Honda and the tuning scene?

It’s hard to say, especially if they keep going in the hybrid direction. It might put a damper on the kind of stuff we do, especially if they keep getting rid of their performance-based cars. But we'll still always have the people who are building and swapping the cars that are on the road now. The only problem is these car's shells won't last forever. But there are plenty of them out there.

There will always be racing, and there will always be people who want to get their car around the track faster. So I’m sure King will always be busy.

If you weren't working with cars or motorcycles for a living, what would you be doing?

I’d probably an engineer of some kind, building things. Right now I have the role of "re-engineering" so it would be nice to be on the other side of things. It would be nice to be designing things for a change.

Do you have a dream car?

Being a Honda guy, I've always liked the NSX. I'd probably set that as my realistic dream car.