(Continued from Part 1 of our Staff Interview with Mike Lindquist)

In Part 2 of our interview with King's Service Manager Mike Lindquist, we talk about customer collaboration, favorite projects, and tuning myths.

I’ve heard that you really take the time to listen and ask questions when customers come to you for a build. What is the initial contact like with your racing customers?

Mike L: Our customers from the Dominican Republic are a recent example. They knew King had been building race cars for years, and they always thought of us as the “go to guys” if they ever built a Honda.

Previously, they were running Mazdas that were ex-US World Challenge or Grand Am cars. The cars were from a company called Tri-Point Engineering, the team that really won with those cars. So once Tri-Point went to the newer Mazda chassis, the older Mazdas got shipped down to the Dominican Republic where our customers raced them. Those Mazdas were kind of heavy, and they’re not as tuner-friendly as the Hondas. The rules are very lax down there.

They called and said, “Hey we know Hondas, we used to race them years ago. We want to go back to the EG hatchback, with a properly built engine. We knew that if we ever did a Honda that you guys would be the people to talk to. Here’s what we’re looking for... here’s what the displacement of the engine needs to be per the rules,” etc. Basically if they tell me the rules, I can come up with something that fits those rules. I send them pictures and dyno charts from previous customer’s builds so they know what we’re talking about throughout the conversation.

We usually go back and forth until we get a quote hammered out. It’s usually a good five or so phone calls (with race engines we’re talking about a project that’s the price of a new Civic, so it’s not something you get done in the first phone call). So the process starts with letting the customer know that we can definitely accomplish their goals. I’ll usually ask them specifics about those goals. Then we go from there: “I have this idea” or “I have that idea.” If they’re ok with my initial ideas, I check the dyno charts for a couple of engines that I’m thinking will fit what the customer’s looking for. They give me feedback like, “This looks good, but can we do this or that?” Then I’ll send them a chart for another variation, and we’ll work on it together and come up with a final build strategy. It’s definitely a team effort between the customer and King.

Usually the race guys pretty much know what they want, so it’s different than talking to a customer that’s less experienced and might be looking for our direction 100% of the way.

So there’s quite a bit of collaborative consulting with the race guys?

Mike L: Right, I won’t build anything or recommend anything that wouldn’t be right. So there have been times when someone has insisted on running a certain part and I’ve had to say, “I’m sorry but we can’t do that part because of reliability issues, and here’s why ....” and I send them pictures of how that part failed in previous builds. That pretty much makes the case. We’re talking from experience, not just personal opinion. Our recommendations are based on facts.

Understandably, customers are used to doing it their own way. Especially overseas, everyone does it differently. They may have theories: “Oh these guys are fast, and they’re doing this ....” They talk to us and we might flip their world upside-down sometimes. At the end of the day what matters is that the customer understands we’re here to help.

So the race rules are a driving force for their goals?

Mike L: Right, that’s pretty much the first thing to consider. I usually start the conversation by asking what the race rules are. They’ll tell me something like, “We’re racing in the Dominican Republic, we have this race that’s 2-liter class, the car has to weigh this much, the only real regulations are stock throttle body and stock intake manifolds. Compression is unlimited, cams are unlimited... what do you think you can do for me?” In any racing, the first question I ask is about the rules: What are your rules? What class are you racing? ...so I know what to start out with, and make sure we’re going the right direction to begin with.

So what about the non-racing customers? What are the common services requested?

Mike L: These customers require anything from full engine builds to simple things like “I have a ‘check engine’ light in a car that I bought modified by the previous owner.”

As far as the engine build customers that come off the street, they’ll say “I really want to make my car go faster, I don’t really care if it’s all motor or turbo.” But I prod them a little bit for what they’re really going to be doing with the car. How do they typically drive it? Do they pound the car from stoplight to stoplight? Do they like driving it in pretty much stock manner versus something they can take to the track on weekends? I try to get a better feel for what the customer does with the car.

Sometimes the customer doesn’t know how to describe what they’re looking for. Which is fine, that’s what I’m here for. I help them along by asking questions about how they’re going to use the car, then suggest a build accordingly. Now, if it’s someone that is really a hands-off car guy (and we’re going to be doing maintenance on the car), we’ll give them a more conservative build as far as reliability of parts... or try to work with the OEM build and see if they’re happy with making 200hp on all-OEM parts and internals. Or if it’s a guy who says he wants to go 12 flat in a street car -- then he’s asking for something that can’t be done with OEM stock parts. So I educate them along the way.

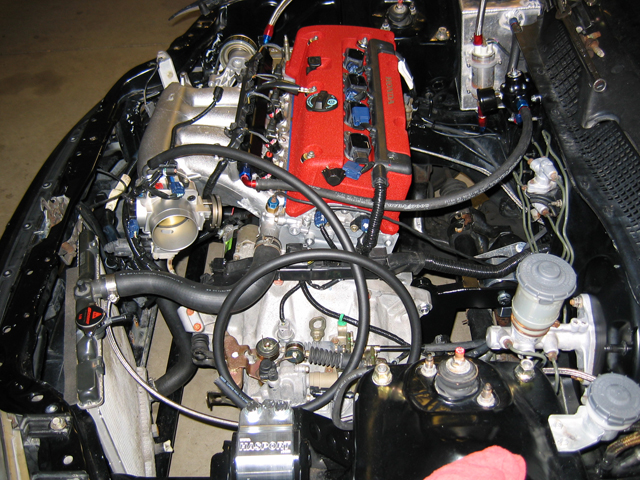

We take pictures of every part of the engine build, and the customer gets a whole file folder with all his pictures from the build. I can sit down with the customer for a visual explanation: “Here’s what we do with the sleeved block, here’s what we do with a non-sleeved block, or here’s what we do when we add valve cover vents to the valve cover, these are the kind of pistons we use .... see this mark here? This is what we machine versus the stock one.” We show it to them in pictures.

A customer can know nothing about parts, but the pictures and my explanation will teach them. That’s a big part of getting the people’s business. I kind of like teaching them, helping them along, you know? We get all kinds of customers. If the customer is willing to take the extra time, I can explain all the stuff to them so they can feel like they have and understand all the facts. I want to make sure they don’t feel like they’re getting “taken” or whatever.

A lot of customers bring us stuff built by other people where they don’t even know what’s inside these engines. They don’t even have an invoice that shows the individual part breakdown, so all they can say is, “I think it has CP pistons, maybe Eagle rods, but I don’t really know.”

So we take the extra steps. Our builds may be more expensive than other places, but a lot of that cost comes from my time spent with them making sure they’re comfortable and on board with everything, as well as our painstaking methods for assembly. The whole build is well-documented with pictures, dyno charts, and itemized invoicing. We make sure everything’s done right.

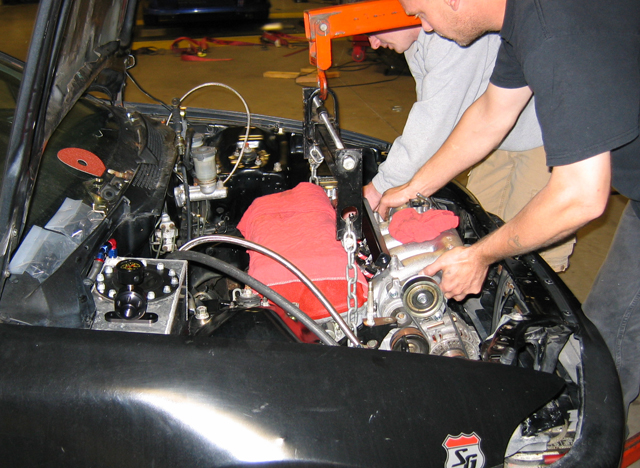

When we’re building an engine, we keep communication flowing with the customers. If they ever call with questions or they stop in, I walk them out to the shop and show them where Chad [King’s engine builder] is. He’s always willing to show people the work in progress. I walk people right in all the time in the middle of him working. I say “Here’s where you motor is, and here’s what we’re thinking about doing with this, and here’s why this is going to better...” I physically show them.

Are there any tuning myths that you have to dispel? Do any customers come in with unrealistic expectations?

Mike L: Well I think the Internet is the worst source when it comes to leading people to draw conclusions based on incomplete or faulty information. There are so many myths, I could talk about them for days. There isn’t a specific one that sticks out to me, since there are so many. But I’d say the concept of “You don’t need tuning,” or “I saw this guy do such and such on the Internet and he got away with using this part or that part,” or “I can run 400hp on stock internals,” or “this guy made 600hp on pump gas, why can’t I?” I have to explain to them, “well, he probably made three pulls before it broke,” or “he’s running a giant turbo and can make a lot of power with a little boost because it’s so huge.”

So they don’t have all the facts?

Mike L: Yeah, or they think they can buy a turbo kit off of eBay and turbo their car the same as someone who turbo’d their car for $8,000, versus a generic $2,000 turbo kit that doesn’t get the same results. They don’t understand why it takes two days to install something that’s “just bolt on.” Well, it’s not so much the bolting on the manifold and turbo that takes time, it’s trying to maintain quality for everything else that goes into the installation. We end up replacing most of the eBay kit parts, making custom parts anyway. Ultimately you’d be better off having us build the kit with the correct parts in the beginning, because we simply won’t put a turbo on with silicone hoses as the oil feed lines instead of a braided line. And we won’t use zip ties instead of proper hose clamps. These eBay kits get really generic. A customer may end up with a turbo that’s just awful and will probably smoke from day one and never stop smoking. So a major myth would be that you can buy an eBay turbo, have us tune it, and expect that everything is going to be just fine. It just doesn’t work that way.

So it sounds like you really have the customer’s best interest at heart...

Mike L: Yes. Sometimes they may not think so at first. But they come around once you go through the explanation and show them you’re not just trying to sell them a part. I explain the reasons in detail, which is something other shops can’t always do. A customer might ask, “Well why do I need a breather kit?” and another shop might dismissively say, “Well, it’s just better.”

But why is it better? If you can explain something technical in terms that customers can understand, it arms them with real knowledge. An informed customer is a happy customer. A customer should never feel like you’re telling them to buy a part they know absolutely nothing about, like they’re only doing it because I said so. Maybe not every shop feels that way but that’s what we try to do for our customers at King.

Do you have any favorite customer projects that come to mind?

Mike L: We have a turbo car that we’re working on. ...These are guys that I drag race against so I know them. Theirs is one of the fastest cars we’ve ever built as far as drag strips go. It hasn’t put down majorly impressive numbers yet but the car’s won events. I was driving the car for them as sort of a “hired driver” to shake out the bugs for them. Got the car to go 10.70 at 135mph. We tuned and did a lot of fabrication on their car; a lot of turbo set up, the fuel system and everything else. It’s a B16 making almost 590hp, and it’s a real small engine.

This winter, we’re taking that same car and building it out to make over 800hp, and they want the car to go mid to low 9’s. We’re stepping it up to a proper 2-liter build and going with a bigger turbo. We’re really turning the corner towards “serious” drag racing now.

That build is a respectable endeavor, financially speaking. Just the gears for the transmission alone are $8,000. So when you get to that level and you’re making that much power, you have to step up your game on all fronts. It’s a great challenge.

I’m an all-motor guy at heart, but the turbos are pretty cool. Getting them to run efficiently is what’s fun. But all-motors are still my first love since it takes so much careful tweaking and so many specific part changes to get to a power goal. I was running 11.1’s making 280hp while another car running 10.70’s is making 583hp or something. It shows that in a car that’s all-motor, you can still make the car fast without making the big power of a turbo car. So I guess I’ve always liked that. I like the responsiveness of an all-motor car.

When I sold the engine out of my old drag car, I used the money to purchase a white Integra Type-R. The Type-R was a theft recovery. The car only had 49k miles on it, and King had done all the work on it, Mugen parts, etc. So I rebuilt it to factory spec as far as the chassis goes, and built a bigger 2.2-liter B-series stroker for it, and that’s been my project that replaced the drag car.

Is that the white Integra Type-R that was parked in King’s showroom at King’s Dyno Day in 2010?

Mike L: No that’s Tim’s car. His has a stock motor and is very, very clean. Mine was parked out front for Dyno Day. Our cars are similar; same year, same white color. Tim’s is just a lot cleaner. He’s got black wheels on his. It’s just immaculate. Mine’s clean, but not that clean. Tim’s is so clean that he’s had it for 10 years and it’s only seen rain twice -- by accident. The engine bay is ridiculous too.

Were there any least favorite customer projects?

Mike L: What comes to mind again are the guys with the eBay turbo kits. The owners spend so much money to get the kit set up right, but the car itself may not be worth all the effort. We get the turbo to the point where it’s reliable, but it still doesn’t make any real power. So we put a lot of time and effort into something that’s mechanically sound, but it’s still not right because of the parts the customer brought to the build. We can’t change those parts if that’s what the customer wanted us to do.

Then there are cars that come in here that are plain scary. They are so dangerous that you’re afraid to drive them. Just tonight, we got a car that the customer shouldn’t even have driven on the road. I took it only ten, twenty feet in the driveway. I got out of it and said, “This is going on the lift, there’s obviously a major problem.” One axle nut was tightened so tight it broke off. If you grab the top and bottom of the wheel and you can wobble it an inch, inch and a half, that’s bad. The only thing that was holding the wheel on the car was the brake rotor and caliper.

The really scary part is that it was a tech at a Honda dealership who originally put the wheel bearings in the car. At a dealership! So that’s even scarier, that people like that work on cars and allow it to go out like that. Basically the wheel was loose because the tech just kept tightening the axle nut until it broke off. So when I took off the wheel, the nut fell on the ground with part of the axle still in it. I took off the wheel and heard “clink!” I looked on the ground and saw that the axle had sheared off and is stuck in the spindle nut. That’s a big nut that requires a 32mm socket.

I can’t say that I have any specific cars that are least favorites. I’d just say that the least favorites are the ones that are just pieced together. I know that everyone can’t have something really cool. It’s respectable to have a car you thought through and did right. Don’t just buy someone else’s botched-together project. It’s a gamble that may not pay off. That’s what we’ve sometimes seen when people don’t have the money to build their own so they just trade cars on Craig’s List and end up getting a pile of junk.

Um, I have to admit I look at those Craig’s List cars too. I’m glad you tell it like it is.

Mike L: I want to make sure I can make every customer comfortable. Some of our customers might be more reserved in personality. They don’t want to feel like they’re getting that snobbish, over-priced tuner shop attitude. We work hard to avoid that stereotype. Street-build customers generally need more explanation and help with developing their build. Also, their budget is tighter. With racing customers it’s a bit more cut and dried. They usually know their cars inside and out, and come to us for specific work. They’re well aware that power and speed cost money and they’re not shocked at the cost. In either case, I really enjoy finding out what their needs are and being able to help them out. We want to make our customers feel comfortable enough where they can speak their minds, and trust they are collaborating with us. I know we’re on the right track when we use plain English instead of stuffy professional-speak that doesn’t really mean anything. Professionalism is important of course, but you have to be able to relate to the customers too. I think that’s the difference between customers that walk in and then right out, versus those that stick around. Being easy to talk to can make the difference on whether someone comes back again.

I do my best to figure out where the customer is coming from. I’ll give customers a shop tour, show them around, and remind them that, “Hey, we’re here to help you. We’re a full-service facility. We aren’t those guys who want your money but don’t care about your car.” Some people focus on our prices, and once in a while we take some heat for it on the Internet. But we have way more customers posting that their money was well spent and they’re really happy with our work and our customer service. The bottom line is that when people come in here, I want them to realize that we’re friendly people who genuinely know our craft and care about the customer’s real needs.