Atari. Nintendo. Sega. These are the platforms of retrogamers, the original video game worshipers that cut their teeth on classics, earning credibility through countless hours of dexterity, problem-solving, creativity and perseverance. These were the days before hard drives, WI-FI and wireless controllers. They were old school.

Mike Lindquist is an old-school Honda tuner. Like an old-school gamer, he cut his teeth on the classics. His platforms of choice? The EG, CRX and EK. He put in the hours: in the books, under the hood and on the road. And those hours paid off on the track.

You might have talked to Mike if you’ve ever called King Motorsports to schedule an oil change, order a part, or just get some advice for your build. Like all the staff at King Motorsports, Mike wears a lot of hats. He’s a scheduler, project manager, consultant, parts expert, account manager, and more. He puts his customers first, and won’t hesitate to steer them away from a part or service that isn’t in their best interest.

I caught up with Mike recently to talk about his old-school roots, his first cars, and more. What follows is Part 1 of his interview, with more to come soon.

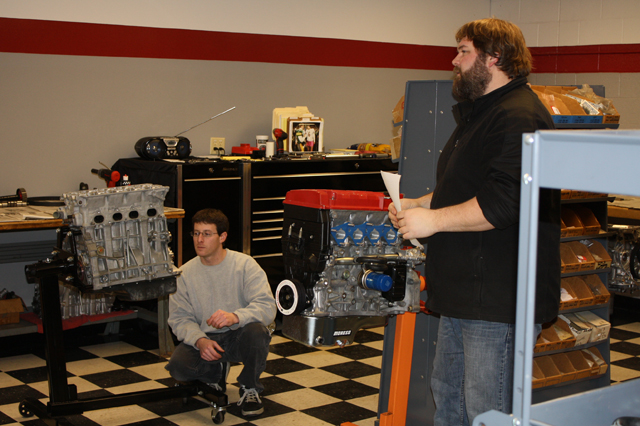

What do you do at King Motorsports?

Mike L.: My job title is “Service Manager” and I also do retail sales and walk-in sales. I also help with any kind of engine build that someone may be inquiring about, or I make recommendations based on ideas a customer already has. Maybe I’ll give them some pointers or discuss parts that might help them. Or, someone might come in who has no idea what they want, and they have a goal – i.e., a power goal, time at a track, or “I want to spend this much money,” or “I want this much power for the money.” Those are all types of things I tackle on a daily basis as far as builds go.

I also handle the day-to-day service work that comes in. “My car’s got a clunk,” “My car’s got a 'check engine' light,” “I want my car tuned, it’s not running good,” any of those things I’ll schedule repairs and quote ahead of time.

How did you get involved with King?

Mike L.: Well I had been working with several different shops through the years around the area, and knew of some of the guys that worked here. Specifically Tim... we knew each other, we both grew up in the same city, went to high school together (he was a grade older than me). We didn’t really know each other so much at the time but we knew of each other as far as he would have customers, he was building motors for friends... and I had my brothers and other friends, so we sort of had a friendly competition just knowing that we both were doing something in the same city. So as I worked through these other shops, I kept in contact with him and then developed more of a friendship. Because of the friendship I was hanging out at King a little bit.

Then one day I was in the shop picking up parts for another shop I was working for and Scott was walking through the shop and kind of just giving Tim some crap because Tim wasn’t there yet. He said “Oh geez, you get here before my own employees.” And I said “Well, that could be changed,” were my exact words. Scott kind of laughed and walked away. Later he asked Tim or Chad if I was serious. I said, “Of course I’m serious when it comes to job openings.” At the time I was driving 62 miles one way to the place I was working at before, doing that for almost three years. So it was getting kind of tiring. So it literally happened that way. They were planning on a new building so I helped with the move over here, moving some of the machinery and stuff one weekend, then pretty much got a fresh start at our current location.

I’ve been with King for 3 years as of October 2010.

What got you started with Hondas? Was it something in particular?

Mike L.: Well it wasn’t so much *something*, as it was *someone*. When I was seventeen, I had a friend with a Civic who wanted to build it out. So I helped him, even though I was more into the domestic stuff at the time. I thought the potential of these motors was good. I was just learning, I was just seventeen. We learned it together. He had been rolling around Honda-Tech a couple years before me, and was into the scene a little more than me. There wasn’t much of a Honda scene at the time (about 1996), around here it wasn’t huge as far as I knew.

We just went from there. I started swapping Hondas before I even owned one. My first engine swap was a 1991 Civic hatchback (EG) for one of my good friends that I’ve known since grade school. We got rid of the DX dual-point engine and put an LS Integra B18A engine in there, and that was kind of a big deal at the time. Back then there weren’t many engine swap kits (just one or two companies making them) and nobody was making adapter harnesses or wiring schematics so you had to figure it out on your own by looking at the factory schematics for both cars and figuring it out. So we had a good time – I spent several nights on that. So for my first swap we put an Integra LS B18A into a 1991 Civic hatchback, which was a standard model so it had a 1.5 liter 4-speed. The car was gold, it was sweet. In fact to this day he still drives it. First engine swap I’ve ever done, and it’s never had a “check engine” light since day one or since. So that was the first thing that really got me into it.

What did you work on before Hondas?

Mike L.: I owned mostly domestic cars, and didn’t really tune them per se. I had a Beretta and a Saturn. The Saturn is probably the car that started me into the whole “tuner world.” It was a ’94, twin cam 1.9 liter. That car was fairly quick. I did a lot of street racing with that car, it had a pretty short geared tranny and those cars didn’t weigh much – you know, the body panels are plastic. The motor had a good amount of potential, and I rebuilt it. I put in an intake manifold and throttle body on it, did all the bolt-ons and put some upgrades from other year cars that had better parts. Got the car pretty quick for an all-motor Saturn. Did suspension and things like that. Then as I was building that car, I was swapping Hondas and realizing that I was just wasting my time with the Saturn, since Hondas just had so much more potential. I had probably swapped like twenty cars before I even thought about getting rid of my Saturn.

So how did you find the info you needed?

Mike L.: Well that was before there was a lot of info about swapping. The only thing I could really find on the Internet at the time were the ECU pin-outs that showed which pin did what. Together with the Haines manual’s wiring schematics (I didn’t have the money to buy factory manuals at the time), I just bought the manuals we could find at the local parts stores, where the wiring was in the back. I mean, most of it was right, but not all of it. You just took the Civic wiring diagram from the Haines manual and the Integra Haines manual with the pin-outs and I sat in a chair. Several nights I was working in my friend’s barn and we actually fell asleep. We were out there all night with the books in our laps, making this wiring octopus. We weren’t sure if it would work, so we put the engine in the car and literally just set it on some 2x12 boards across the radius arms. We lifted the motor and tranny with our hands and just set it in there. So it was literally just sitting on boards, just enough so that we could hook up the wiring and the fuel to it and see if the thing would start.

We ran the wires outside the car, through the window and just temporarily hooked them up to see if we were even on the right track. It fired up! I was actually holding the motor – it wasn’t hooked up to motor mounts or anything – because it was literally just sitting on a board. When we fired it up, it ran the first time, with no "check engine" light. We were like “Holy cow,” you know, all the time we spent was actually worth it, double checking everything. Then we took it back out and finalized the wiring, re-installed it, and he has literally had it in there ever since. It was probably 1999 when we did that swap, and we just kind of figured it out. After that I started working on other people’s cars that were the same vintage, and starting to get the hang of it. I was swapping a fair amount of cars on the side, for friends and making some side cash.

At the time I wasn’t working at any car-related places. I was working at a television repair place, doing a lot of home theater and satellite installations. I repaired a lot of TVs and things like that. Did a lot of soldering. After that I started doing more landscaping for my friend’s dad at a pretty decent landscaping business. So I cut grass and did maintenance on his stuff during the day, and then I would rent a bay out at the local salvage yard and work on the swaps at nighttime. The salvage yard would buy cars that had swaps in them; I would tell them which cars to buy since they didn’t know what a swap was – they would just sell the engine and tranny as separate pieces as replacements for local shops. I said “you should start leaving these together, we can stick them in these cars.” They said, “We’ll give you a cheap deal per swap – just pay like $50 for bay costs for selling our product.” So I was basically doing that.

So what was the first Honda that you bought?

Mike L.: My first Honda was a CRX HF. It was baby blue. I can’t say I remember where I bought it from, I don’t remember if I did a trade for that car, or what. It was a shell, without a motor in it. It was pretty rusty. I took that car, filled the quarter panels with expanding foam and painted over it so it didn’t look so bad. Welded a little cage in the car, a real simple one (it had square tubing actually), and then I put a single-cam VTEC into it from a ’94 Civic. Stock motor, with a bunch milled off the head. The car was super light – it weighed 1650 because it was so stripped out. It pretty much ran the bare essentials to drive on the road legally. I raced around with that car a little bit, it was pretty much my first one. I think I had that car at the same time as the Saturn, so that was my little project car I was kind of playing with, like a “beater” I guess.

Then I got rid of the Saturn. Actually the engine block cracked in the Saturn because I had a radiator hose blow (it was winter) and I quick-filled it with water to get back home. I forgot to plug in the block heater that night, and the water expanded and cracked the aluminum so that was pretty much junk.

Then I ran across a silver ’97 Civic EK hatchback at a local dealership. The same dealership that sold me the Saturn. It was a Chicago car, stock standard Civic with 120k miles on it. That was my first car where I really started putting swaps into it, you know, it was a B-series. I had that car from 125k miles on that chassis, and sold it with 294k miles on the chassis to a friend of mine. I had seven motors in it during that time. Just kept changing motors as I ran into different deals, every engine was just a little bigger than the last one. I sold that car to a friend of mine once I started working at King. So I had that car pretty much my whole “Honda career” up to then. When I sold it I still got $4k for the car and it was awful. But it was fast, so that’s what sold it. The car went 14 flat in the quarter so it wasn’t a slouch for a street car. It was nothing fancy but it was pretty good. He drove it for a year or so and then sold it to a friend. It’s been through five owners since him, and the car’s still on the road. One of the kids that owns it now knows me here, and called me and told me it was at the track running the same times as it did before, and the car’s got 330k miles on the chassis now. The motor’s still untouched. I built that motor with used parts, and I put 100k miles on those used parts … those bearings have got over 250k miles on them. It was an LS VTEC with used pistons from another customer’s build. Put new rings in it, just honed it, never bored it, ran standard sized pistons, threw some Type-R cams in it. Pretty much just left all the bearings. Didn’t even put a new oil pan gasket on it. I just ran it bare bones and I drove that car every single day for that 62 mile commute for three years, racking up the miles on it. It still got 32 miles to the gallon and was fast. So I pretty much just drove that car to the ground, and it’s still going. That’s probably the car I’ve had the longest.

I saw a video of you (on the King Motorsports YouTube channel) in an EG Civic drag car, what’s the story there?

Mike L.: At the time I had that EK Civic, I started building my drag car. While working at the salvage yard, I bought an EG Civic hatchback for like $500, it was automatic with a blown head gasket. I stripped the car out, then randomly acquired parts from cars we got in the auction, or I’d do jobs in exchange for payment in parts. The first time I got the car down the track, it was running low 13’s. Then I started working my way into the 12’s. I think the fastest I got that car to go with the 1.8 liter was 12.6, then with a 2.0 liter I got the time down to 11.78. I was running 11.80’s with 220 horsepower.

The show 'Name That Test and Tune' (before it was called 'Pass Times') was recording for their show pilot at our local drag strip. When I heard about it I decided to go check it out. We got a ton of people who came there to show off their cars and such. It turned out I was one of the faster imports there, so they picked me to represent the imports on the show. It was a fun time doing it - the video is up on YouTube. I wish the car hadn’t bogged as much as it did, but it was still a decent run at the time.

I got the car up to 282 HP to the wheels and the car did 11.1. And that was the fastest I got it. So the whole time I was driving my EK I was also working on my drag car, which I raced for six years. Went to a lot of import events with that car, traveled, raced it in Ohio, Norwalk, and ran a lot of the stuff around here. I retired the car when I started working at King. We started using it as a test chassis here at King. We put engines into the car, dyno them, break them in, etc.

We used that car as a test chassis for one of my customers is in Bahrain. They have road racing and an F1 race circuit in Bahrain. They race in import events there, and we’ve built a lot of motors for them. We needed a car to test the engines and break them in because we don’t have an engine dyno, so that’s how my drag car became our test chassis. It still sits here in the back with no motor in it, but I’m still planning on doing something with it at some point I think.

You have a customer in the Middle East?

Mike L.: Oh yeah, we have customers from all over the world. A lot of our customers aren’t in the States actually. They could go anywhere in the world (to have their engines built), but they say that the US builds the best engines as far as reliability and power. All the cars that are really fast in Dubai are getting built by people in the States. Bahrain is an island in Persian Gulf - the track that these customers use for their drag races is the F1 track. Pretty much nothing’s there except for an F1 track. When F1’s not there, they fill it with other events. They have a series they race in during the spring and fall, because it’s too hot in the summer. They said that people stop working at noon because it’s so hot. They said it gets 55 to 60 degrees Celsius there (about 131 to 140 degrees Fahrenheit). We developed a good relationship with them and offered the installation services (installing and breaking in their engines on a test car) because they wanted us to give them a tune for the engine. But we needed to do a little R&D because it was actually a restrictor motor class and we had never built a K Series with a restrictor on it. They were K series engines; one was running an EG and other was running a Del Sol. It was a 2-liter class, so we built K20’s. They had to run a 50mm restrictor on the intake pipe. So after some R&D we designed and built a custom header and engines and everything for them. We used my old drag car as a test chassis for the R&D (this allows the engines to be dropped in turn-key: completely broken-in engines with Hondatas and intakes, already tuned).

Where else around the world are your customers?

Mike L.: King’s owner, Scott, has customers from all over the place too. For me, I have engine build customers in the Caribbean, Turks and Caicos Islands, Santo Domingo Dominican Republic, Guyana, Puerto Rico, Grand Cayman, all over. The guys in Turks and Caicos are rally car guys. We’ve built a couple motors for them. One has a rally EG, the other is a rally EK, and they travel the cars around and rally them. They have classes for those cars -- half tarmac, half dirt, depending on where they’re at. They’re not running against cars that are all-wheel drive. They ship those cars all around.

I have customers in Canada who do a lot of ice racing. One guy has a CRX that’s an ice race car, with spikes in the wheels and they do like an autocross on the ice. So we’ve done a lot of work with his car.

How do these international customers find King? Do they call you or just fly in and surprise you?

Mike L.: It always starts with a call, and they inquire about our engine build services. Maybe they heard by word of mouth, a lot call after seeing our website. I talk to them about what we can do based on what their race rules are. I send them some dyno charts – I know every chart from our dyno almost by heart. So when they mention what they want to do, I can pick out a dyno chart that would be similar to what they’re asking for, and send it over. We can show real results from something they’re asking for. That seems to sell a lot of the builds -- once they realize they’re talking to people that really understand what’s possible, I think that’s what sells it. So they’re willing to spend the money to ship the stuff around to make sure they get something good.

King’s reputation has always been good before my time here. But I’d like to think I’m adding an extra level on the technical engine side.