In the shop recently we are preparing an EK Civic SCCA STL race car. First up- TIG welding door bars:

Next- AIM MXL data aq unit mounted in a very cool carbon fiber inlay:

Dashboard mock up. Check out the KMS custom fabricated adjustable steering shaft....

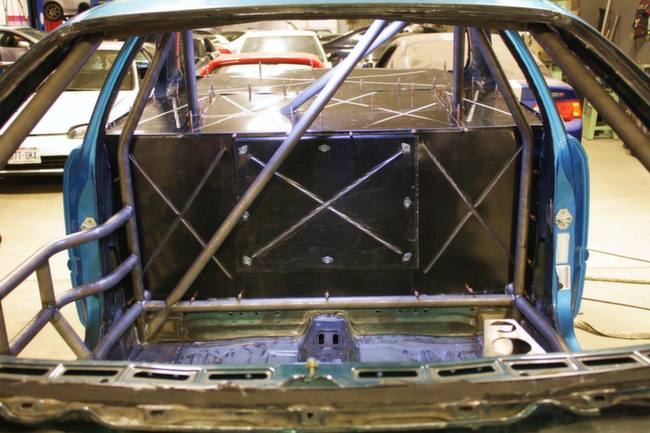

Just a few more bars and this EK Civic STL roll cage will be complete. Next step is all the tin work to separate the fuel cell from the drivers compartment.

Just a few more bars and this EK Civic STL roll cage will be complete. Next step is all the tin work to separate the fuel cell from the drivers compartment.

Finishing up work bulkhead work on the SCCA STL Civic race car. All aluminum panels are hand fit and then bead rolled for strength. The center section is attached with self ejecting DZUS fasteners for easier access to the fuel cell, fuel pump etc. All other panels are pop riveted in place.

The SCCA STL Civic heads to the body shop today for paint. Back in a few weeks for final assembly! Big thanks to Kyle Gessler of Gessler's Auto for the outstanding service!

Call us today for custom roll cages, race prep and fabrication!

http://www.kingmotorsports.com/c-248-roll-cages.aspx

http://www.kingmotorsports.com/c-242-fabrication.aspx