In late November we posted up pictures of the prep and loading of a special Mugen shipment leaving Tokyo. We're happy to say that the shipment has officially arrived to our facility here in Wisconsin, USA!

Although this shipment contains a variety of Mugen parts, the lion's share of the cargo allocation was for the FRP Mugen S2000 hardtops. We've already pre-sold most of this shipment's hardtops and they will head out to customers very soon. The remaining hardtops will go fast so if you've been eyeing one of these quality pieces, now's a good time to order since (for now) they are in stock and ready to ship!

Here are pics of this latest Mugen shipment, freshly unloaded in the warehouse area of our facility! You're looking at ten Mugen S2000 hardtops, Mugen wheels, Mugen SS S2000 bumpers, DC5 aero and more ...

How do you start a journey of over 6000 miles? With a single step!

New Mugen parts are shipped to us directly from Tokyo, Japan. This particular shipment includes ten S2000 hardtops and various other body parts (such as for the DC5). There are countless boxes to track, load up, and transport ... many people are involved in thinking through the logistics. The containers are transported by our partners like Vantec World Transport. By the time we ship these Mugen parts to you, they will have traveled thousands of miles over land and sea.

These pictures come from a shipment scheduled to arrive to our facility in New Berlin, Wisconsin on or about December 26, 2012. It will take about 5 weeks in all for the parts to complete their journey.

Thanks to our friends at Mugen for snapping these pics of the trucks getting loaded up!

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

Get your orders in soon for these high quality FRP (fiber reinforced polymer) Mugen S2000 hardtops! Once they arrive at our facility in late December they will be ready to ship out ASAP to your door.

We've dug up a few additional pictures of these high quality hardtops, shown here on the Mugen S2000 Prototype. This prototype features a CRFP (carbon fiber reinforced polymer) hardtop, which is identical to the production FRP hardtop -- the only difference is the construction material.

The unpainted Mugen hardtop and hood create a stunning contrast on Spa Yellow!

Here is one of the first Mugen brochures for the S2000 from early in 2000.

Here is the heart of the Mugen-equipped S2000:

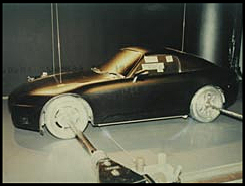

Mugen spent considerable time in the wind tunnel developing their body parts for the S2000. The phrase "Form follows function" has never been more true! The Mugen Aero: S2000 SS - Front Splitter for AP2 is still available.

Our favorite Mugen body kit for the S2000 is the "SS Style" body it. The kit was based on the Mugen Speed Star 2200 (SS2200) concept vehicle. Love it!

Bonus images: Here are pictures of the Mugen S2000 prototype parked behind Mugen HQ in early 2000. These prototypes were in constant use endurance testing new parts and doing promo track work for Mugen.

This was part of our original ad campaign for S2000 parts:

King Motorsports went on to build our own Mugen SS2000 in red. King currently still stocks Mugen Aero pieces for the 2000-2003 S2000 and 2004-2009 S2000.

FRP is an acronym for Fiber Reinforced Polymer. Some will say that it stands for Fiber Reinforced Plastic, but this is incorrect – Not all plastics are polymers. In the case of Mugen’s manufacturing process, they use a proprietary FRP composite developed in-house after much testing in the lab, wind tunnel and street.

Some of Mugen’s aero pieces are constructed from FRP exclusively; bumper covers, side sills, spoilers. But Mugen manufactures two items from both Carbon Fiber and FRP – Hoods for Fit, and S2000, and S2000 Hardtops. The reasoning is pretty straightforward, Carbon Fiber construction is the strongest, lightest material available for these parts, but it comes at a cost. FRP, on the other hand, offers a lower cost option. While not as strong or light as Carbon Fiber, FRP is still extremely strong and still lighter that most other materials. Most importantly, it can be used in the same molds as the Carbon Fiber pieces, therefore offering the same precise fit that Mugen’s Carbon Fiber parts are known for.

Here are a few common questions regarding Mugen’s FRP parts:

Q: What is the weight difference between the Carbon Fiber and FRP parts?

A: The weight difference is about 25%. For instance, the Carbon Fiber Hood for the S2000 weights 34 lbs – the FRP unit weighs X44 lbs.

Q: How well does the FRP top fit?

A: The fit is perfect, just like Mugen’s Carbon Fiber Top. The same molds are used to produce both.

Q: Does the top come with all of the mounting hardware?

A: All the necessary hardware is included, as is the Polycarbonate rear window.

Q: What is required to get FRP parts ready to paint?

A: All of Mugen’s FRP parts come primed and ready for paint. Your body shop will only need to give them a light scuffing and thorough cleaning.

Q: Should I test-fit my FRP parts first, or can I go ahead and paint them knowing that they will fit?

A: It’ll fit, period. Paint it, install it and enjoy.

Below are some technical data regarding FRP (source: American Composites manufacturers Association):

Not all plastics are composites. In fact, the majority of plastics today are pure plastic, like toys and soda bottles. When additional strength is needed, many types of plastics can be reinforced (usually with reinforcing fibers). This combination of plastic and reinforcement can produce some of the strongest materials for their weight that technology has ever developed...and the most versatile.

Therefore, the definition of a fiber-reinforced polymer (FRP) composite is a combination of :

-a polymer (plastic) matrix (either a thermoplastic or thermoset resin, such as polyester, isopolyester, vinyl ester, epoxy, phenolic)

-a reinforcing agent such as glass, carbon, aramid or other reinforcing material such that there is a sufficient aspect ratio (length to thickness) to provide a discernable reinforcing function in one or more directions.

FRP composite may also contain:

- fillers

- additives

- core materials

... that modify and enhance the final product. The constituent elements in a composite retain their identities (they do not dissolve or merge completely into each other) while acting in concert to provide a host of benefits ideal for structural applications including:

** High Strength and Stiffness Retention - composites can be designed to provide a wide range of mechanical properties including tensile, flexural, impact and compressive strengths. And, unlike traditional materials, composites can have their strengths oriented to meet specific design requirements of an application.

** Light Weight/Parts Consolidation - FRP composites deliver more strength per unit of weight than most metals. In fact, FRP composites are generally 1/5th the weight of steel. The composite can also be shaped into one complex part, often times replacing assemblies of several parts and fasteners. The combination of these two benefits makes FRP composites a powerful material system- structures can be partially or completely pre-fabricated at the manufacturer's facility, delivered on-site and installed in hours.

** Creep (Permanent Deflection Under Long Term Loading) - The addition of the reinforcement to the polymer matrix increases the creep resistance of the properly designed FRP part. Creep will not be a significant issue if the loads on the structure are kept below appropriate working stress levels.

** Resistance to Environmental Factors - Composites display excellent resistance to the corrosive effects of:

** Freeze-thaw: because composites are not attacked by galvanic corrosion and have low water absorption, they resist the destructive expansion of freezing water.

** Weathering and Ultra-Violet Light: FRP composite structures designed for weather exposure are normally fabricated with a surface layer containing a pigmented gel coat or have an ultraviolet (UV) inhibitor included as an additive to the composite matrix. Both methods provide protection to the underlying material by screening out UV rays and minimizing water absorption along the fiber/resin interface.

** Chemicals and Temperature: Composites do not rust or corrode and can be formulated to provide long-term resistance to nearly every chemical and temperature environment. Of particular benefit, is composites ability to successfully withstand the normally destructive effects of de-icing salts and/or saltwater spray of the ocean.

** Fire Performance of Composites - FRP composites can burn under certain conditions. Composites can be designed to meet the most stringent fire regulations by the use of special resins and additives. Properly designed and formulated composites can offer fire performance approaching that of most metals.