The following article comes to us via King customer Andy Thompson - thanks Andy for this deep dive into a Honda classic!

****

Honda has historically produced some of the most intriguing small sporty cars: the CR-X, Beat, and City Turbo to name a few. I’d like to take a step back and look at the car that started the trend, the Honda S600. I have grown a great appreciation for this car and will focus on some of the closer details that make this car so special.

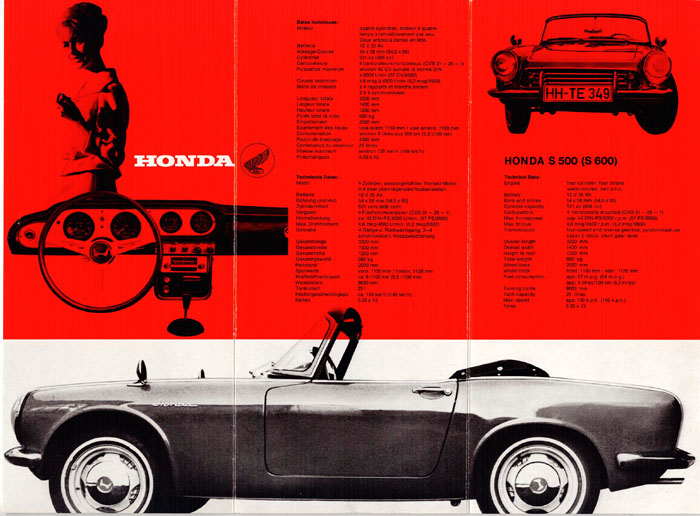

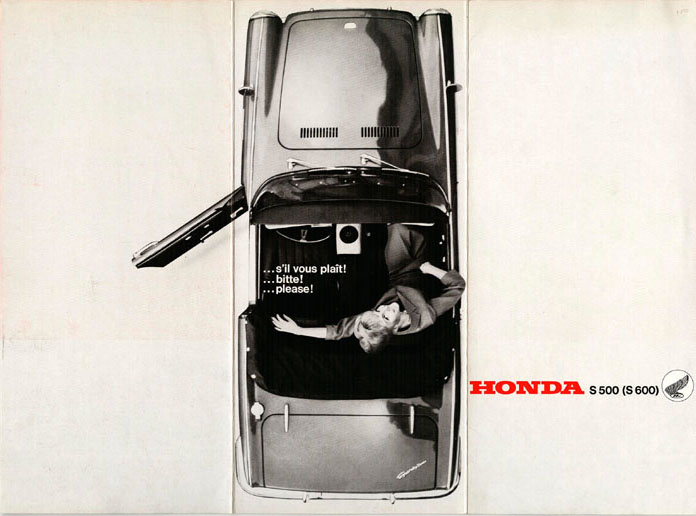

In a time where British and Italian companies such as MG, Triumph and Fiat were the primary producers of roadsters, Honda dared to enter the competition with almost no history in automotive design besides the Honda T360. Although the first actual car produced by Honda was the S360 -- unveiled on June 5th, 1962 -- it was never actually put into production due to lack of power. The S500 followed very shortly after in 1963 as a full production model. Although these preceded the S600, I will focus specifically on the S600 -- produced between 1964 and 1966 -- as it was the first majorly successful automobile by Honda.

Chassis

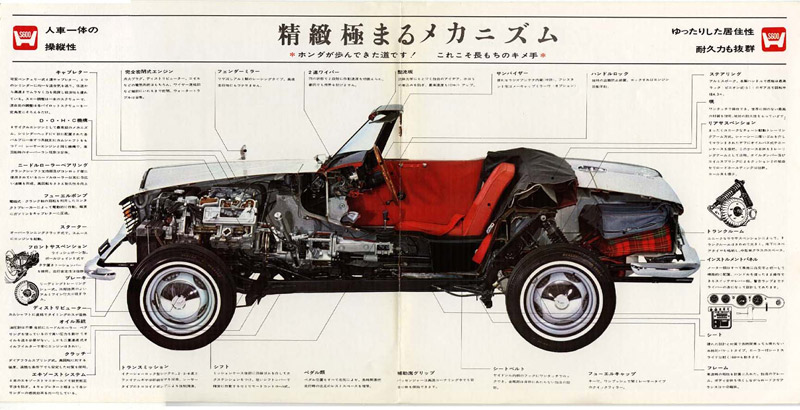

Roadsters of the 1960s were completely different vehicles than what we know of as a car today. The S600 consisted of a lightweight steel unibody with almost no safety features. Vehicles of this time hardly ever used plastic body panels. This roadster’s delicate chrome bumpers wrapped tightly around the chassis. The slightly arched rear quarter panels offered just enough contour, without disrupting a functional shape. This design style was found on other roadsters of the time and is quite pronounced in the popular Triumph Spitfire.

The S600 was not designed to be the fastest car of the time, but instead to offer the joy of driving in what has been called a motorcycle in car form. The convertible top offered the option to enjoy the world around the driver. The small body was similar to other roadsters of the time, such as the MG Midget. This popular style pushed the focus of automotive travel towards driving and experiencing the car, rather than just getting to a destination.

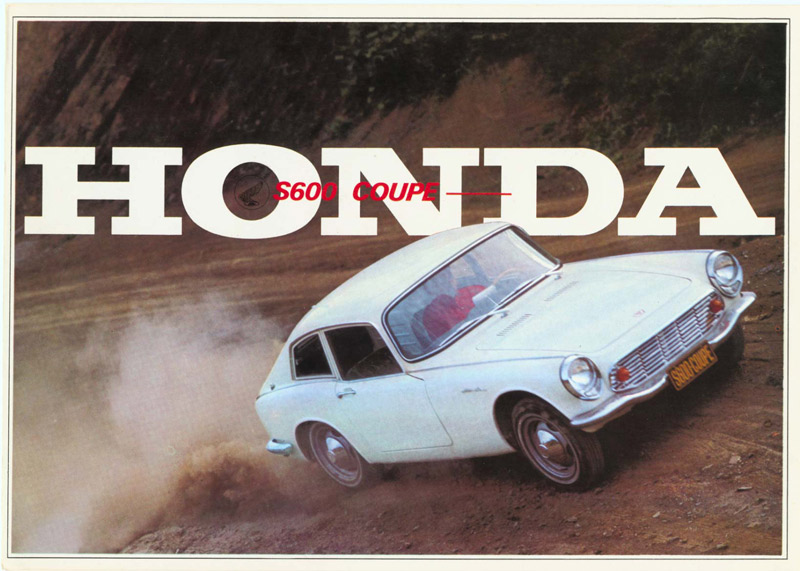

The S600 was offered as a traditional roadster as well as a “coupe” in standard and SM trim levels. Having various body styling and trim options is somewhat expected in today’s age -- but in the 60s, it was quite rare!

The concept of converting a performance-oriented roadster into a hard top fast back variant gave birth to a styling design that can today be referred to as a shooting brake. Shooting brakes are an uncommon but intriguing body style, as they add a sort of unbalanced complexity to the rear region of an otherwise streamline styled roadster. With this they bring a sort of exotic shape which offers better aerodynamics and generally allows the manufacture to extrude the quarter panels out far past the rear quarter windows.

Shooting brake cars never took the spotlight as only 1,800 S600 coupes were produced as compared to 11,284 convertibles. Similar sales trends can be seen between the Triumph Spitfire and its coupe counterpart the GT6. Honda didn’t pay any less attention to the coupe, as it offered the “SM” trim line to both body styles.

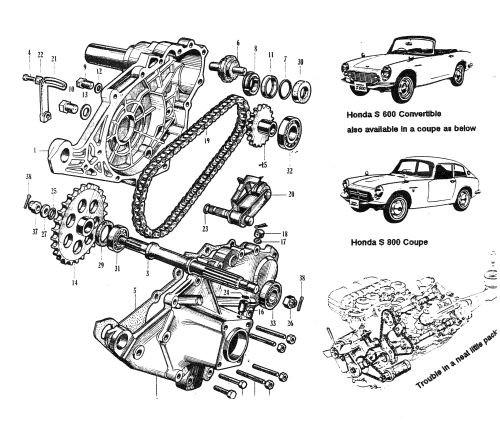

Engine

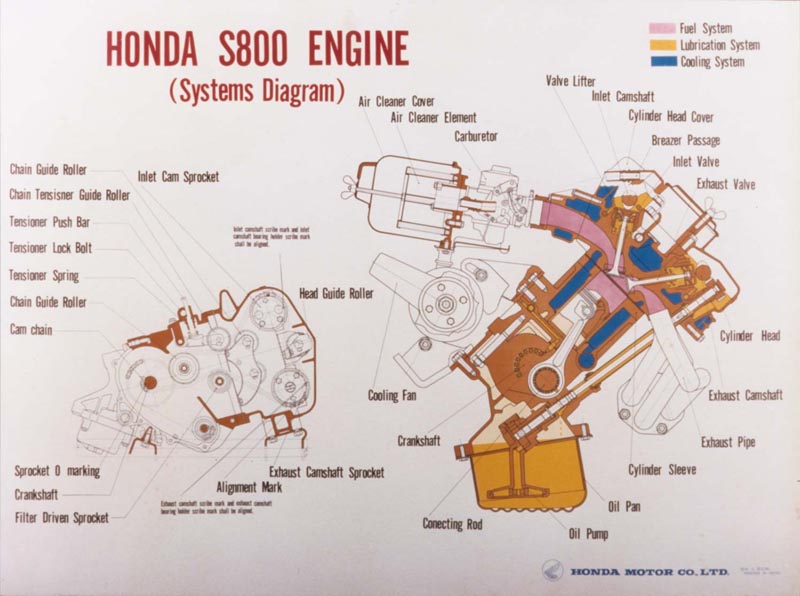

Honda engines are known for their efficiency through such small displacement. The S600’s 606cc engine was no exception. The engine consisted of a DOHC, all aluminum, water-cooled, quad Keihin carb, inline four producing 57 hp. Almost 100 HP per liter! This sounds quite familiar to what Honda has become known to produce, and was quite an accomplishment for 1964 as other competing cars were using much larger displacement engines such as the 1.8 liter found in the MG B and the 2.1 liter engine found in the Triumph TR4.

It goes without saying that for Honda to produce enough horsepower out of an engine one-third the size of its competition, it had to rev. In this case, the magic number was 8500 rpm. Which continued to a redline of 9500 rpm.

In order to keep the hood low, the engine was designed to sit in the bay at an extreme slant. I have included a diagram of the similar S800 engine to show how pronounced this slant is. This slant is similar to that of a four cylinder motorcycle.

Drivetrain

The drivetrain may very well be my favorite part of this little car. Like other roadsters of the time, the S600 consisted of a front engine, rear wheel drive platform equipped with a four-speed transmission. In order to achieve power to the wheels out of such a small engine, they chose to use a 6.42:1 final drive -- extremely short gearing. Short enough to cause complaints of seeing 7000 rpm cruising at 70 mph on the freeway and causing quite a bit of noise. Keep in mind this car was originally designed for the tight city streets of Japan.

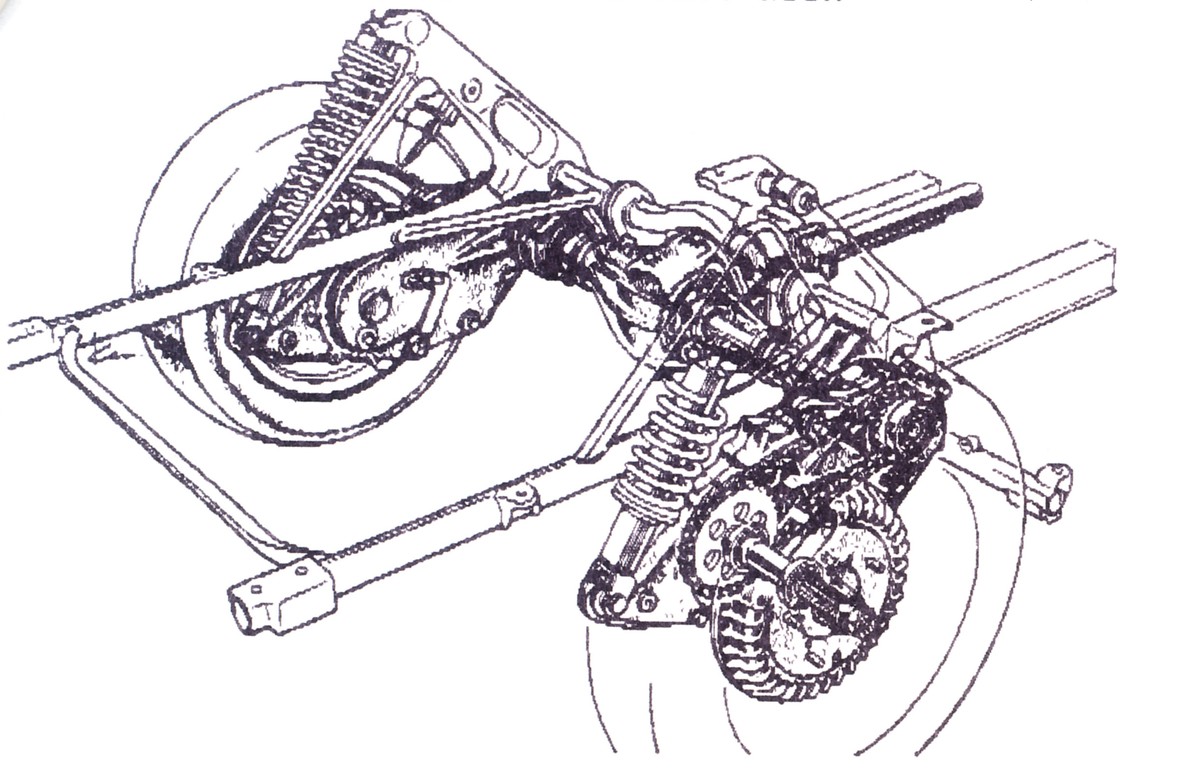

In the 60s, many automotive manufactures were tinkering with ways to offer independent rear suspension in their performance vehicles instead of a traditional solid rear axle. At the time, the constant velocity joints found in modern axles were very uncommon.

Honda had a solution. Instead of placing the rear transfer case in parallel with the rear wheels. They set it forward in line with the hinge point of the rear trailing arms. The driveshaft would turn into the transfer case and two straight shafts exited the case on either side. A chain drive system connected the exit shafts to the rear wheels. Thus allowing for a fully independent suspension with no constant velocity joints. This system is very similar to how a motorcycle transfers power to the rear wheel, but applied to a car. I have always thought this to be an amazing adaption of design and quite ingenious for the time. This mechanical genius makes the S chassis unique to the rest.

Complimenting the fully independent suspension was a very modern spring-on-strut shock absorber system. The rear shock were mounted at a drastic angle, moving the suspension lower and yielding more trunk space.

The S600 is a beautiful little machine that really shows that exotic ideas can be incorporated into an intriguing package. Although it is said that Honda never turned a profit off their early sports cars, they set a foundation of what is expected out of a small, sporty Japanese sports car: Light weight, proper handling, and a flexible high revving engine. The original S Chassis truly is a machine of another time.

The following review comes to us via King customer Andy Thompson - thanks Andy!

****

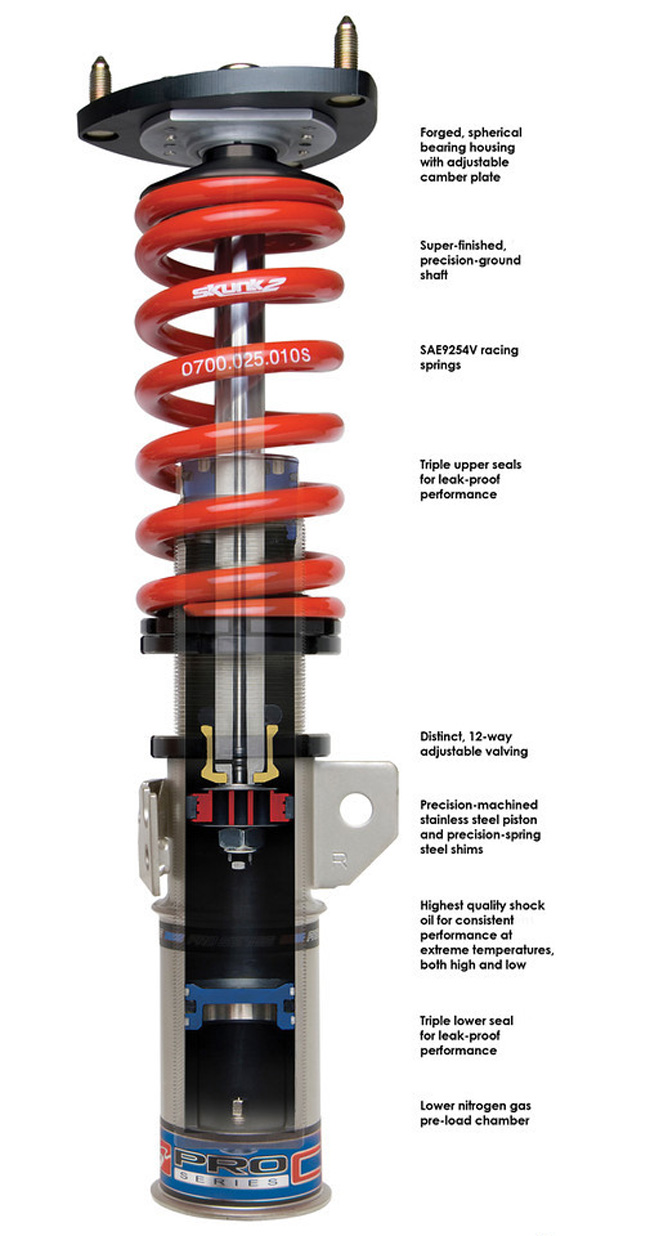

Skunk2’s Pro-C Coilovers are a solid choice for an all-inclusive, mid-level suspension offering features beneficial to track-specific applications.

Why I Chose Pro-C

I initially set out to find an authentic suspension that offered modern coilover features and chassis-specific production. Although many with newer vehicles will not have this issue, my dated EF chassis has quite limited aftermarket choices. So the Pro-C was one of my only choices.

Skunk2 designs and tests all of their products, specific to application. This is important because the coilover actually matches the intended chassis it was designed for, instead of a coilover that was originally designed for one chassis and has been translated to fit others.

I wanted a fully-inclusive suspension that had springs matched to struts, versus a two-piece spring and strut combination from two separate manufactures. I wanted fully independent adjustability in spring rate, dampening, and ride height. The Pro-C smartly offers ride height adjustability independent of spring rate. With many older suspensions, changing ride height also adjusts the spring rate as a negative side effect.

I was also interested in an inverted mono tube strut to maintain a larger oil capacity while offering strength and responsiveness. The Pro-C does not offer inversion, but still uses a mono tube design versus an OE style struts twin tube design (which can feel unresponsive in performance applications).

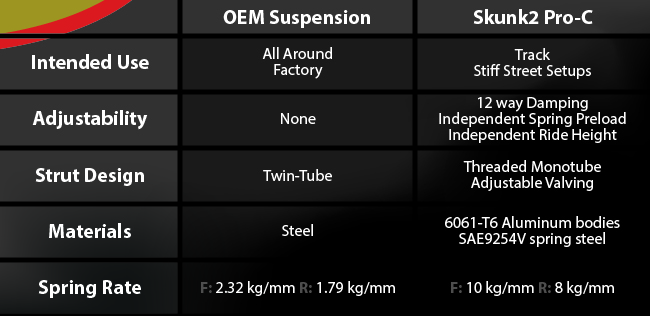

Here is a comparison of the EF OEM suspension versus the Pro-C:

Pros

12-Way Valving

The Pro-C offers a relatively simple and effective valving system. Removable keys on the top of the strut easily control dampening. The keys are retained to the top of the piston rod via rubber o-rings, which allow them to be left in place during driving.

Many lower quality suspensions advertise 36-way adjustability, which is fine, but can be quite frustrating to keep track of and count out when readjusting damping. With Skunk2 offering 12 points of adjustability, it gives the user enough range to dial in damping with meaningful differences between each click. I currently have my suspension set at 3 in the front and 5 in the rear, for casual street driving.

CNC Machined Aluminum Strut housing and Spring Perches

If you live anywhere with rain, snow, or dirt; aluminum threading and perches are a huge deal. A common issue with lower quality aluminum and steel struts is corrosion, and trying to adjust spring rate after any amount of time usually involves ditching the spanner wrenches and grabbing a punch and hammer. The Pro-Cs are made of 6061-T6 aluminum, which is a tempered grade. This makes the threading much more corrosion-resistant and spring rate adjustability a feature that persists despite your weather or road conditions.

I have two summer seasons on my coilovers, in which they still adjust with ease after road grime is wiped off. I personally apply silicon lubricant to threading to repel water (although road grim builds up quicker but is easily removable).

Cons

Street Comfort

Contrary to what is advertised, these coilovers are by no means comfortable. With almost no spring load and low dampening settings, you will still be feeling every crack in the street. On the other hand, the feeling is confident, and there is a total absence of slack in the system. That said, make sure the rest of your suspension system and bushings are up to par-- if not, expect the soft spot in your system to be amplified.

Clearances with UCA

Although this is not a coilover specific issue, some double wishbone suspension setups with front camber kits may run into clearance issues with certain degrees of camber. On my EF, I am running an irrational 4.6 degrees of camber in the front, in which occasionally my front knuckle knocks against the springs and spring perches of the coilover on larger bumps.

Final Word

If you’re a Honda enthusiast looking to get involved in some motor sports such as local auto cross events or open road racing events -- while still being able to drive your car on the street -- this is definitely a great choice.

If you’re planning on driving your car every day or commute long distance to work, the Pro-C may not be for you. Or consider purchasing the Pro-C with lower spring rates.

I am constantly tinkering with my suspension and plan to try a different set of springs for summer 2015. Thanks for reading.

Detailed look at the Pro-C:

****

See more Skunk2 Racing products at the King Motorsports online store!

http://www.kingmotorsports.com/m-43-skunk2-racing.aspx

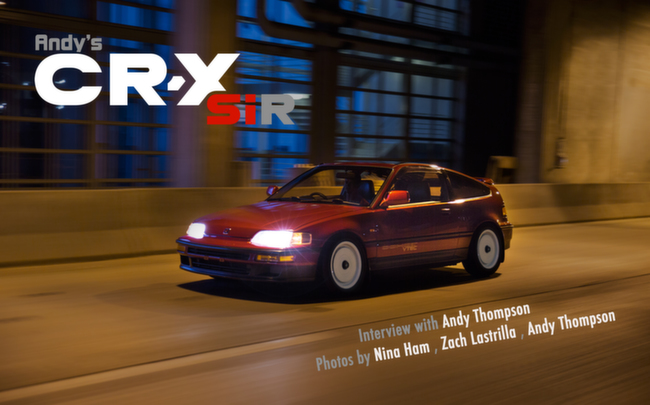

We don’t have to tell you there are passionate Honda owners all over the world. We’ve helped countless enthusiasts achieve their goals, whether it’s a fully-built race car or a daily driver that performs and looks great on the street. One of these enthusiasts is Andy Thompson – and he lives right here in Wisconsin. He’s local to our facility in New Berlin, Wisconsin and is close enough to stop by from time to time. We were lucky enough to see his amazingly clean CR-X SiR at our 2014 Dyno Day event.

His CR-X is a 100% legally imported JDM RHD beauty that took over 3 months to locate and import in 2008. Because Andy imported it, he’s the first and only Stateside owner. He took it from fairly rough shape and has built up an “OEM perfection” build that stays true to the period and is fueled by Andy’s background in both graphic design and mechanical engineering. If you ask us, that’s a potent education for crafting a clean ride. Good taste plus the skills to achieve your vision? That’s a win-win combo.

The love he’s put into his old school Honda definitely deserves a special showcase, so we caught up with Andy to get the 411 on his build. Andy says that compliments can be hard to come by in the import scene, but I think you’ll agree his CR-X deserves them.

Why a CR-X?

Andy: I feel that many people forget to realize the fact that vintage Japanese cars can hold as much history as any other car. It’s true that many older Japanese cars are built like cheap utilities -- including the Honda CR-X -- but that doesn’t make them any less important than any other car in the scope of automotive history. Many of us grew up with affordable tuner cars, including myself, buying my first CR-X at 13 and owning five EFs before I even bothered to try a different car (an S2000), but unlike many, I can’t just forget and leave the EF chassis behind.

At 17 I sold off almost everything I owned in order to seize the opportunity to bring this CR-X into the US -- fully legal and VIN matched. The car was sold as an extremely dirty rolling shell, with engine shipped separate, but it was all there. Rust free, and most importantly able to be registered just before the laws changed.

Having owned a CR-X since 13, I had grown an undivided love towards the weird little cars, and knew instantly that this car had the potential I was looking for.

Classy choices for a teenager Andy! You were raised right! Tell us about your CR-X.

Andy: The exact model is a 1990 EF8 SiR Glasstop in Torino Red Pearl. For a little background info, SiRs were only made in Steel roof and Glasstop models. The Glasstop was a rare dealer option, in which was only sold in black and red. The red models were extremely rare as compared to the black, in which I only know of one that resides in the US at this time.

Since 2008, I have been slowly working at this car to build an example of one of the cleanest CR-X projects while paying respect to what Honda intended when their engineers designed this lovable little machine. I continually strive for OEM perfection, and aftermarket modifications that complement the vehicle in a vintage grip car sort of manner.

Every year I try to do something interesting to the car. This past spring, I completed an EK9 32 mm 5-lug conversion with EK9 brakes in order to fit a set of extremely rare DP Motorsport Pacific wheels I picked up brand new in box from 1987. Because I have a BS in Graphic Design, visual and complementary aesthetics are very important to me; these era-specific turbine wheels were perfect for the car.

Wait so you found classic wheels that are even older than your car? And they were brand new?

Andy: Yes-- I purchased the wheels earlier this year from a guy in Ohio. The wheels were manufactured in 1987 and were still brand new, unused in their original boxes. 2 of the 4 were still sealed in their original bags never opened. So the wheels had sat for 27 years before I got a hold of them.

Holy cow that is awesome. What were the next mods?

Andy: The 5-lug swap project became quite an ordeal once I got into it, including sandblasting and powdercoating most of the suspension and brakes -- and acquiring a lot of new hardware, ball joints, bearings, etc. I met Scott at King Motorsports earlier this year and knew he was the guy to help me tie up all of the loose ends on my laundry list of parts to make the conversion happen.

What does the future hold for you and your CR-X?

Andy: Currently I am very happy with how the car sits. If I were to list future plans for the car, the top of the list would include new old stock front and rear bumpers, trim, and side moldings; OEM fog lights; and a working bumper pole (I have one, it’s just junk). I am also always on the look for old rare wheels, and would love to find a set of SSR Air Stage or Auswuch for it.

I’m happy with the stock B16 engine, it runs perfect and all accessories work, including the AC, thank god. Perhaps unrealistically, I have always considered a Honda N22 swap (I’m a pretty big diesel fan). I think a very interesting project could come about from the swap.

I’m very thankful that King Motorsports is able to help keep these “golden era” Hondas on the road. Valuable resources like that don’t come around often.

Enjoy my CR-X and remember to keep the classics alive!

Exterior

Complete matching VIN Real EF8

Torino Red Pearl Color

JDM SiR Cyber Top (glass roof, rare option)

JDM SiR Wing

JDM SiR front lip

JDM SiR Power folding mirrors

JDM SiR Amber glass

JDM Window visors

Interior

JDM NSX Seats

JDM SiR Back seats

JDM ATC Sprint Steering wheel (Mugen Horn Button)

JDM Mitsubishi Mini Disk Player/CD Player

HKS Shift knob

Cartiva Bamboo Floor Mats

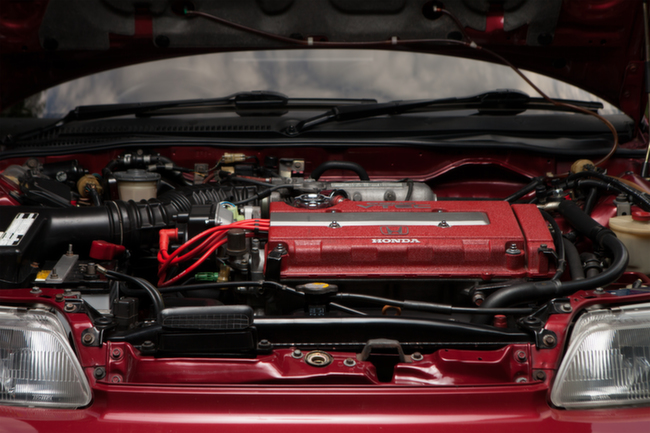

Engine

Original matched B16A

HKS Sport Exhaust

JDM Integra Type R Valve Cover

JDM Integra Type R Oil Cap

Suspension

Skunk 2 Pro C Coilovers

Function 7 Lower Control Arms (Spherical Bearings)

ASR Subframe Brace

Spoon lower tie bar

Skunk 2 Pro Series adjustable control arms front

Skunk 2 Pro Series adjustable control arms rear

EK9/ITR 5 lug Front Spindles (Machined for SiR/DA Wheel Bearing)

EK9/ITR 5 Lug Rear Spindles

Powdercoated DA Front Knuckles

Powdercoated EK9 Rear hubs

Brakes

Powdercoated EK9 Front Calipers

Powdercoated EK9 Rear Calipers

OEM EK9 Brake Rotors

Techna Fit Braided Stainless Steel Brake Lines

Project Mu NS 400 Brake Pads

Wheels

15 X 6.5 +18 1987 DP Motorsport Pacific Wheels

185/55 R15 Yokohama S Drive Tires

Mugen Lug Nuts

Volk Rays Valve Stems

See more pics on Andy’s Flickr account:

https://www.flickr.com/photos/108200011@N02/sets/72157646023680793/

Find parts for your CR-X on King's online store:

http://kingmotorsports.com/s-86-crx.aspx